Filter News

Area of Research

- Advanced Manufacturing (2)

- Biological Systems (1)

- Biology and Environment (47)

- Clean Energy (43)

- Computational Biology (1)

- Fusion and Fission (7)

- Fusion Energy (2)

- Isotopes (2)

- Materials (46)

- Materials for Computing (6)

- National Security (5)

- Neutron Science (36)

- Nuclear Science and Technology (2)

- Quantum information Science (2)

- Supercomputing (36)

News Type

News Topics

- (-) Bioenergy (50)

- (-) Clean Water (14)

- (-) Composites (6)

- (-) Exascale Computing (25)

- (-) Frontier (24)

- (-) Materials (41)

- (-) Microscopy (20)

- (-) Neutron Science (47)

- (-) Physics (28)

- (-) Sustainable Energy (43)

- (-) Transportation (27)

- 3-D Printing/Advanced Manufacturing (37)

- Advanced Reactors (8)

- Artificial Intelligence (46)

- Big Data (22)

- Biology (58)

- Biomedical (28)

- Biotechnology (11)

- Buildings (18)

- Chemical Sciences (22)

- Climate Change (48)

- Computer Science (82)

- Coronavirus (17)

- Critical Materials (2)

- Cybersecurity (14)

- Decarbonization (45)

- Education (1)

- Emergency (2)

- Energy Storage (28)

- Environment (101)

- Fossil Energy (4)

- Fusion (30)

- Grid (23)

- High-Performance Computing (43)

- Hydropower (5)

- Isotopes (27)

- ITER (2)

- Machine Learning (22)

- Materials Science (44)

- Mathematics (6)

- Mercury (7)

- Microelectronics (2)

- Molten Salt (1)

- Nanotechnology (16)

- National Security (35)

- Net Zero (8)

- Nuclear Energy (54)

- Partnerships (16)

- Polymers (8)

- Quantum Computing (20)

- Quantum Science (30)

- Renewable Energy (1)

- Security (11)

- Simulation (30)

- Software (1)

- Space Exploration (12)

- Summit (30)

- Transformational Challenge Reactor (3)

Media Contacts

The International Standards Organization has put its stamp of approval on 18 nuclear analytical chemistry methods at ORNL. These testing and calibration methods have received ISO 17025 accreditation.

Growing up exploring the parklands of India where Rudyard Kipling drew inspiration for The Jungle Book left Saubhagya Rathore with a deep respect and curiosity about the natural world. He later turned that interest into a career in environmental science and engineering, and today he is working at ORNL to improve our understanding of watersheds for better climate prediction and resilience.

With the world’s first exascale supercomputer now fully open for scientific business, researchers can thank the early users who helped get the machine up to speed.

Researchers at the Department of Energy’s Oak Ridge National Laboratory were the first to use neutron reflectometry to peer inside a working solid-state battery and monitor its electrochemistry.

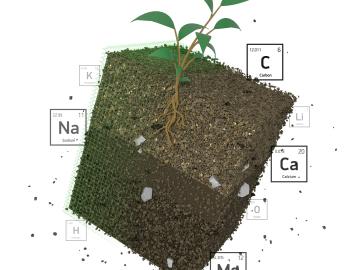

Oak Ridge National Laboratory researchers recently demonstrated use of a laser-based analytical method to accelerate understanding of critical plant and soil properties that affect bioenergy plant growth and soil carbon storage.

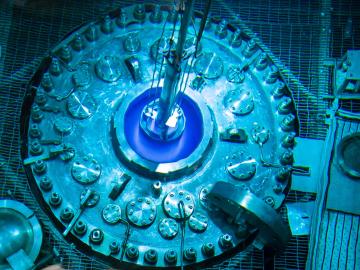

Creating energy the way the sun and stars do — through nuclear fusion — is one of the grand challenges facing science and technology. What’s easy for the sun and its billions of relatives turns out to be particularly difficult on Earth.

Ken Herwig's scientific drive crystallized in his youth when he solved a tough algebra word problem in his head while tossing newspapers from his bicycle. He said the joy he felt in that moment as a teenager fueled his determination to conquer mathematical mysteries. And he did.

To support the development of a revolutionary new open fan engine architecture for the future of flight, GE Aerospace has run simulations using the world’s fastest supercomputer capable of crunching data in excess of exascale speed, or more than a quintillion calculations per second.

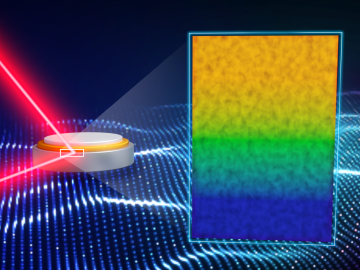

When opportunity meets talent, great things happen. The laser comb developed at ORNL serves as such an example.

For more than 100 years, Magotteaux has provided grinding materials and castings for the mining, cement and aggregates industries. The company, based in Belgium, began its international expansion in 1968. Its second international plant has been a critical part of the Pulaski, Tennessee, economy since 1972.