Filter News

Area of Research

- Advanced Manufacturing (16)

- Biological Systems (2)

- Biology and Environment (53)

- Biology and Soft Matter (1)

- Building Technologies (1)

- Clean Energy (82)

- Computational Biology (1)

- Computational Engineering (1)

- Computer Science (5)

- Electricity and Smart Grid (1)

- Functional Materials for Energy (1)

- Fusion and Fission (11)

- Fusion Energy (2)

- Materials (75)

- Materials for Computing (10)

- National Security (12)

- Neutron Science (18)

- Nuclear Science and Technology (3)

- Quantum information Science (3)

- Supercomputing (51)

News Type

News Topics

- (-) 3-D Printing/Advanced Manufacturing (85)

- (-) Artificial Intelligence (67)

- (-) Bioenergy (71)

- (-) Chemical Sciences (42)

- (-) Composites (19)

- (-) Frontier (28)

- (-) Nanotechnology (40)

- (-) Physics (38)

- Advanced Reactors (26)

- Big Data (42)

- Biology (81)

- Biomedical (43)

- Biotechnology (14)

- Buildings (42)

- Clean Water (27)

- Climate Change (77)

- Computer Science (137)

- Coronavirus (32)

- Critical Materials (15)

- Cybersecurity (23)

- Decarbonization (56)

- Education (1)

- Emergency (2)

- Energy Storage (74)

- Environment (158)

- Exascale Computing (28)

- Fossil Energy (4)

- Fusion (47)

- Grid (46)

- High-Performance Computing (65)

- Hydropower (11)

- Irradiation (3)

- Isotopes (40)

- ITER (6)

- Machine Learning (34)

- Materials (107)

- Materials Science (97)

- Mathematics (7)

- Mercury (10)

- Microelectronics (2)

- Microscopy (39)

- Molten Salt (7)

- National Security (45)

- Net Zero (10)

- Neutron Science (86)

- Nuclear Energy (86)

- Partnerships (22)

- Polymers (22)

- Quantum Computing (26)

- Quantum Science (44)

- Renewable Energy (1)

- Security (15)

- Simulation (41)

- Software (1)

- Space Exploration (23)

- Statistics (1)

- Summit (38)

- Sustainable Energy (95)

- Transformational Challenge Reactor (4)

- Transportation (72)

Media Contacts

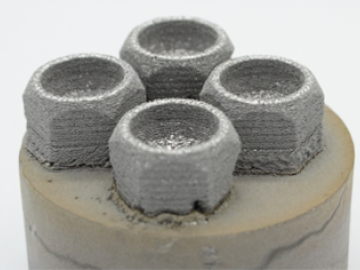

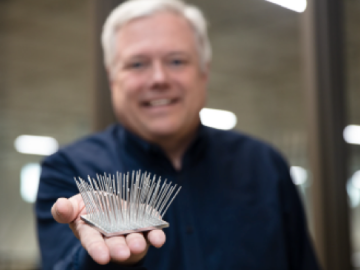

Using additive manufacturing, scientists experimenting with tungsten at Oak Ridge National Laboratory hope to unlock new potential of the high-performance heat-transferring material used to protect components from the plasma inside a fusion reactor. Fusion requires hydrogen isotopes to reach millions of degrees.

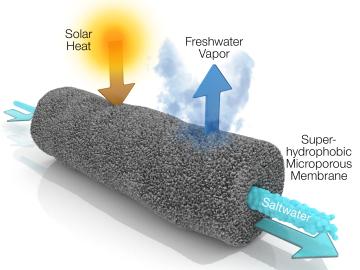

A new method developed at Oak Ridge National Laboratory improves the energy efficiency of a desalination process known as solar-thermal evaporation.

Early career scientist Stephanie Galanie has applied her expertise in synthetic biology to a number of challenges in academia and private industry. She’s now bringing her skills in high-throughput bio- and analytical chemistry to accelerate research on feedstock crops as a Liane B. Russell Fellow at Oak Ridge National Laboratory.

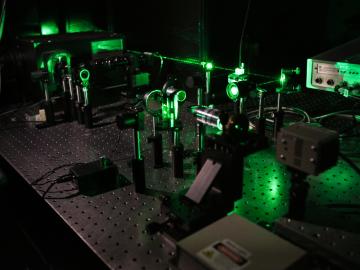

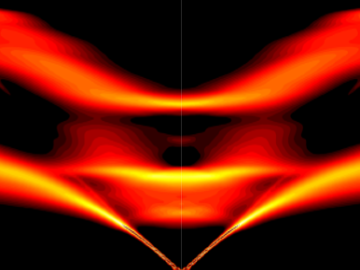

Scientists at Oak Ridge National Laboratory studying quantum communications have discovered a more practical way to share secret messages among three parties, which could ultimately lead to better cybersecurity for the electric grid

Researchers at Oak Ridge National Laboratory are taking inspiration from neural networks to create computers that mimic the human brain—a quickly growing field known as neuromorphic computing.

In the shifting landscape of global manufacturing, American ingenuity is once again giving U.S companies an edge with radical productivity improvements as a result of advanced materials and robotic systems developed at the Department of Energy’s Manufacturing Demonstration Facility (MDF) at Oak Ridge National Laboratory.

A study led by Oak Ridge National Laboratory explored the interface between the Department of Veterans Affairs’ healthcare data system and the data itself to detect the likelihood of errors and designed an auto-surveillance tool

Scientists have discovered a way to alter heat transport in thermoelectric materials, a finding that may ultimately improve energy efficiency as the materials

A novel additive manufacturing method developed by researchers at Oak Ridge National Laboratory could be a promising alternative for low-cost, high-quality production of large-scale metal parts with less material waste.

When Scott Smith looks at a machine tool, he thinks not about what the powerful equipment used to shape metal can do – he’s imagining what it could do with the right added parts and strategies. As ORNL’s leader for a newly formed group, Machining and Machine Tool Research, Smith will have the opportunity to do just that.