Filter News

Area of Research

- Advanced Manufacturing (4)

- Biological Systems (1)

- Biology and Environment (18)

- Clean Energy (26)

- Computational Biology (1)

- Computational Engineering (1)

- Computer Science (5)

- Electricity and Smart Grid (1)

- Functional Materials for Energy (1)

- Fusion Energy (1)

- Isotopes (1)

- Materials (18)

- Materials for Computing (4)

- National Security (3)

- Neutron Science (3)

- Nuclear Science and Technology (1)

- Supercomputing (19)

News Type

News Topics

- (-) Big Data (22)

- (-) Bioenergy (22)

- (-) Biomedical (15)

- (-) Composites (13)

- (-) Exascale Computing (4)

- (-) Frontier (4)

- (-) Machine Learning (14)

- (-) Polymers (14)

- 3-D Printing/Advanced Manufacturing (50)

- Advanced Reactors (18)

- Artificial Intelligence (23)

- Biology (25)

- Biotechnology (3)

- Buildings (29)

- Chemical Sciences (26)

- Clean Water (13)

- Climate Change (32)

- Computer Science (57)

- Coronavirus (15)

- Critical Materials (13)

- Cybersecurity (9)

- Decarbonization (15)

- Energy Storage (48)

- Environment (60)

- Fossil Energy (1)

- Fusion (18)

- Grid (25)

- High-Performance Computing (23)

- Hydropower (6)

- Irradiation (3)

- Isotopes (15)

- ITER (4)

- Materials (68)

- Materials Science (54)

- Mathematics (2)

- Mercury (3)

- Microscopy (20)

- Molten Salt (6)

- Nanotechnology (24)

- National Security (12)

- Net Zero (3)

- Neutron Science (42)

- Nuclear Energy (36)

- Partnerships (8)

- Physics (10)

- Quantum Computing (6)

- Quantum Science (14)

- Security (4)

- Simulation (12)

- Software (1)

- Space Exploration (11)

- Statistics (1)

- Summit (8)

- Sustainable Energy (56)

- Transformational Challenge Reactor (1)

- Transportation (49)

Media Contacts

Research teams from the Department of Energy’s Oak Ridge National Laboratory and their technologies have received seven 2021 R&D 100 Awards, plus special recognition for a COVID-19-related project.

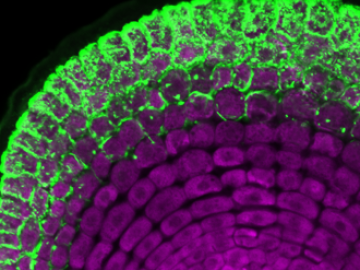

An ORNL team has successfully introduced a poplar gene into switchgrass, an important biofuel source, that allows switchgrass to interact with a beneficial fungus, ultimately boosting the grass’ growth and viability in changing environments.

Pengfei Cao, a polymer chemist at ORNL, has been chosen to receive a 2021 Young Investigator Award from the Polymeric Materials: Science and Engineering Division of the American Chemical Society, or ACS PMSE.

A research team at Oak Ridge National Laboratory have 3D printed a thermal protection shield, or TPS, for a capsule that will launch with the Cygnus cargo spacecraft as part of the supply mission to the International Space Station.

A research team led by Oak Ridge National Laboratory bioengineered a microbe to efficiently turn waste into itaconic acid, an industrial chemical used in plastics and paints.

Oak Ridge National Laboratory researchers, in collaboration with Cincinnati Inc., demonstrated the potential for using multimaterials and recycled composites in large-scale applications by 3D printing a mold that replicated a single facet of a

Oak Ridge National Laboratory researchers combined additive manufacturing with conventional compression molding to produce high-performance thermoplastic composites reinforced with short carbon fibers.

Thirty-two Oak Ridge National Laboratory employees were named among teams recognized by former DOE Secretary Dan Brouillette with Secretary’s Honor Awards as he completed his term. Four teams received new awards that reflect DOE responses to the coronavirus pandemic.

A new Department of Energy report produced by Oak Ridge National Laboratory details national and international trends in hydropower, including the role waterpower plays in enhancing the flexibility and resilience of the power grid.