Filter News

Area of Research

- (-) Advanced Manufacturing (20)

- (-) Biology and Environment (54)

- Building Technologies (3)

- Clean Energy (123)

- Climate and Environmental Systems (4)

- Computational Engineering (3)

- Computer Science (13)

- Energy Sciences (1)

- Fusion and Fission (2)

- Fusion Energy (3)

- Isotopes (2)

- Materials (51)

- Materials for Computing (11)

- Mathematics (1)

- National Security (19)

- Neutron Science (15)

- Nuclear Science and Technology (4)

- Quantum information Science (4)

- Sensors and Controls (1)

- Supercomputing (63)

News Type

News Topics

- (-) 3-D Printing/Advanced Manufacturing (27)

- (-) Artificial Intelligence (5)

- (-) Clean Water (3)

- (-) Computer Science (9)

- (-) Environment (30)

- (-) Polymers (1)

- (-) Security (1)

- (-) Sustainable Energy (17)

- Advanced Reactors (2)

- Big Data (2)

- Bioenergy (20)

- Biology (31)

- Biomedical (7)

- Biotechnology (7)

- Buildings (2)

- Chemical Sciences (8)

- Climate Change (16)

- Composites (7)

- Coronavirus (8)

- Critical Materials (1)

- Cybersecurity (2)

- Decarbonization (4)

- Energy Storage (5)

- Fusion (2)

- Grid (3)

- High-Performance Computing (8)

- Hydropower (3)

- Isotopes (2)

- Machine Learning (4)

- Materials (14)

- Materials Science (8)

- Mercury (1)

- Microscopy (3)

- Molten Salt (1)

- Nanotechnology (5)

- National Security (1)

- Net Zero (1)

- Neutron Science (3)

- Nuclear Energy (3)

- Partnerships (5)

- Physics (1)

- Simulation (5)

- Space Exploration (1)

- Summit (3)

- Transformational Challenge Reactor (2)

- Transportation (3)

Media Contacts

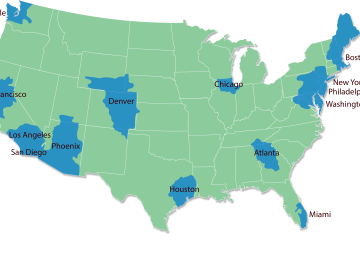

Oak Ridge National Laboratory worked with Colorado State University to simulate how a warming climate may affect U.S. urban hydrological systems.

A research team at Oak Ridge National Laboratory have 3D printed a thermal protection shield, or TPS, for a capsule that will launch with the Cygnus cargo spacecraft as part of the supply mission to the International Space Station.

Scientists at Oak Ridge National Laboratory added new plant data to a computer model that simulates Arctic ecosystems, enabling it to better predict how vegetation in rapidly warming northern environments may respond to climate change.

Scientists studying a unique whole-ecosystem warming experiment in the Minnesota peatlands found that microorganisms are increasing methane production faster than carbon dioxide production.

An analysis published in the Proceedings of the National Academy of Sciences and led by researchers from the U.S. Department of Energy’s Oak Ridge National Laboratory has received the 2021 Sustainability Science Award from the Ecological Society of America.

Oak Ridge National Laboratory researchers combined additive manufacturing with conventional compression molding to produce high-performance thermoplastic composites reinforced with short carbon fibers.

A team of Oak Ridge National Laboratory researchers demonstrated that an additively manufactured hot stamping die – a tool used to create car body components – cooled faster than those produced by conventional manufacturing methods.

Stan Wullschleger has been selected as the associate laboratory director for the Biological and Environmental Systems Science Directorate, or BESSD, at ORNL.

A study by Oak Ridge National Laboratory, the University of Copenhagen, the National Park Service and the U.S. Geological Survey showed that hotter summers and permafrost loss are causing colder water to flow into Arctic streams, which could impact sensitive fish and other wildlife.

Oak Ridge National Laboratory researchers have demonstrated that a new class of superalloys made of cobalt and nickel remains crack-free and defect-resistant in extreme heat, making them conducive for use in metal-based 3D printing applications.