Filter News

Area of Research

- Advanced Manufacturing (20)

- Biology and Environment (28)

- Building Technologies (3)

- Clean Energy (109)

- Computational Engineering (1)

- Computer Science (9)

- Energy Sciences (1)

- Fusion and Fission (12)

- Fusion Energy (9)

- Isotope Development and Production (1)

- Isotopes (4)

- Materials (80)

- Materials Characterization (2)

- Materials for Computing (15)

- Materials Under Extremes (1)

- National Security (11)

- Neutron Science (19)

- Nuclear Science and Technology (9)

- Quantum information Science (4)

- Supercomputing (35)

- Transportation Systems (1)

News Type

News Topics

- (-) 3-D Printing/Advanced Manufacturing (74)

- (-) Big Data (24)

- (-) Decarbonization (29)

- (-) Fusion (24)

- (-) Machine Learning (25)

- (-) Materials (93)

- (-) Quantum Science (37)

- (-) Space Exploration (13)

- (-) Sustainable Energy (75)

- Advanced Reactors (23)

- Artificial Intelligence (45)

- Bioenergy (39)

- Biology (39)

- Biomedical (28)

- Biotechnology (10)

- Buildings (34)

- Chemical Sciences (41)

- Clean Water (15)

- Climate Change (45)

- Composites (19)

- Computer Science (99)

- Coronavirus (28)

- Critical Materials (23)

- Cybersecurity (20)

- Education (3)

- Element Discovery (1)

- Energy Storage (74)

- Environment (79)

- Exascale Computing (11)

- Fossil Energy (2)

- Frontier (16)

- Grid (36)

- High-Performance Computing (40)

- Hydropower (6)

- Irradiation (2)

- Isotopes (23)

- ITER (5)

- Materials Science (85)

- Mathematics (2)

- Mercury (5)

- Microelectronics (1)

- Microscopy (27)

- Molten Salt (8)

- Nanotechnology (38)

- National Security (21)

- Net Zero (5)

- Neutron Science (77)

- Nuclear Energy (46)

- Partnerships (30)

- Physics (28)

- Polymers (21)

- Quantum Computing (14)

- Renewable Energy (1)

- Security (12)

- Simulation (15)

- Statistics (2)

- Summit (27)

- Transformational Challenge Reactor (4)

- Transportation (60)

Media Contacts

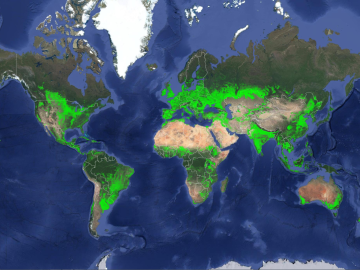

ORNL climate modeling expertise contributed to a project that assessed global emissions of ammonia from croplands now and in a warmer future, while also identifying solutions tuned to local growing conditions.

ORNL researchers have developed a novel way to encapsulate salt hydrate phase-change materials within polymer fibers through a coaxial pulling process. The discovery could lead to the widespread use of the low-carbon materials as a source of insulation for a building’s envelope.

Corning uses neutron scattering to study the stability of different types of glass. Recently, researchers for the company have found that understanding the stability of the rings of atoms in glass materials can help predict the performance of glass products.

Ateios Systems licensed an ORNL technology for solvent-free battery component production using electron curing. Through Innovation Crossroads, Ateios continues to work with ORNL to enable readiness for production-quality battery components.

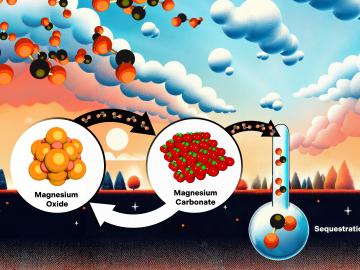

Magnesium oxide is a promising material for capturing carbon dioxide directly from the atmosphere and injecting it deep underground to limit the effects of climate change. ORNL scientists are exploring ways to overcome an obstacle to making the technology economical.

ORNL and Caterpillar Inc. have entered into a cooperative research and development agreement, or CRADA, to investigate using methanol as an alternative fuel source for four-stroke internal combustion marine engines.

Four researchers at the Department of Energy’s Oak Ridge National Laboratory have been named ORNL Corporate Fellows in recognition of significant career accomplishments and continued leadership in their scientific fields.

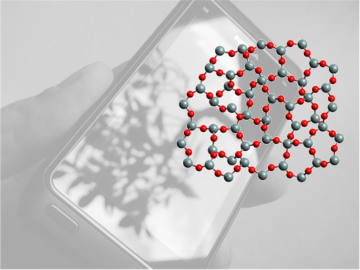

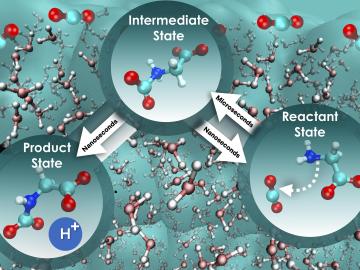

Recent research by ORNL scientists focused on the foundational steps of carbon dioxide sequestration using aqueous glycine, an amino acid known for its absorbent qualities.

Effective Dec. 4, Gina Tourassi will assume responsibilities as associate laboratory director for the Computing and Computational Sciences Directorate at the Department of Energy’s Oak Ridge National Laboratory.

Four scientists affiliated with ORNL were named Battelle Distinguished Inventors during the lab’s annual Innovation Awards on Dec. 1 in recognition of being granted 14 or more United States patents.