Filter News

Area of Research

- Advanced Manufacturing (12)

- Biology and Environment (5)

- Building Technologies (1)

- Clean Energy (54)

- Computational Engineering (1)

- Computer Science (6)

- Electricity and Smart Grid (1)

- Fusion and Fission (5)

- Fusion Energy (6)

- Materials (21)

- Materials for Computing (4)

- National Security (7)

- Neutron Science (2)

- Nuclear Science and Technology (5)

- Quantum information Science (3)

- Sensors and Controls (1)

- Supercomputing (6)

News Type

News Topics

- (-) 3-D Printing/Advanced Manufacturing (44)

- (-) Fusion (16)

- (-) Grid (28)

- (-) Machine Learning (17)

- (-) Molten Salt (5)

- (-) Nanotechnology (18)

- (-) Quantum Science (12)

- Advanced Reactors (15)

- Artificial Intelligence (18)

- Big Data (24)

- Bioenergy (33)

- Biology (40)

- Biomedical (21)

- Biotechnology (7)

- Buildings (29)

- Chemical Sciences (20)

- Clean Water (20)

- Climate Change (38)

- Composites (12)

- Computer Science (53)

- Coronavirus (17)

- Critical Materials (14)

- Cybersecurity (9)

- Decarbonization (25)

- Energy Storage (45)

- Environment (81)

- Exascale Computing (4)

- Fossil Energy (1)

- Frontier (4)

- High-Performance Computing (20)

- Hydropower (8)

- Irradiation (2)

- Isotopes (16)

- ITER (4)

- Materials (42)

- Materials Science (46)

- Mathematics (6)

- Mercury (7)

- Microscopy (20)

- National Security (19)

- Net Zero (4)

- Neutron Science (35)

- Nuclear Energy (34)

- Partnerships (1)

- Physics (20)

- Polymers (14)

- Quantum Computing (5)

- Security (7)

- Simulation (11)

- Space Exploration (10)

- Statistics (1)

- Summit (8)

- Sustainable Energy (59)

- Transportation (47)

Media Contacts

Scientists at Oak Ridge National Laboratory studying quantum communications have discovered a more practical way to share secret messages among three parties, which could ultimately lead to better cybersecurity for the electric grid

Researchers at Oak Ridge National Laboratory are taking inspiration from neural networks to create computers that mimic the human brain—a quickly growing field known as neuromorphic computing.

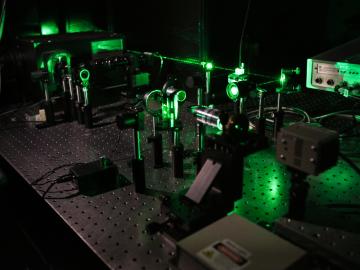

Oak Ridge National Laboratory physicists studying quantum sensing, which could impact a wide range of potential applications from airport security scanning to gravitational wave measurements, have outlined in ACS Photonics the dramatic advances in the field.

A study led by Oak Ridge National Laboratory explored the interface between the Department of Veterans Affairs’ healthcare data system and the data itself to detect the likelihood of errors and designed an auto-surveillance tool

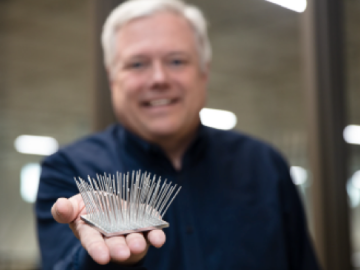

A novel additive manufacturing method developed by researchers at Oak Ridge National Laboratory could be a promising alternative for low-cost, high-quality production of large-scale metal parts with less material waste.

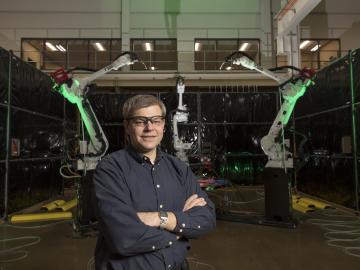

When Scott Smith looks at a machine tool, he thinks not about what the powerful equipment used to shape metal can do – he’s imagining what it could do with the right added parts and strategies. As ORNL’s leader for a newly formed group, Machining and Machine Tool Research, Smith will have the opportunity to do just that.

Scientists at Oak Ridge National Laboratory have developed a low-cost, printed, flexible sensor that can wrap around power cables to precisely monitor electrical loads from household appliances to support grid operations.

Alex Roschli is no stranger to finding himself in unique situations. After all, the early career researcher in ORNL’s Manufacturing Systems Research group bears a last name that only 29 other people share in the United States, and he’s certain he’s the only Roschli (a moniker that hails from Switzerland) with the first name Alex.

Vera Bocharova at the Department of Energy’s Oak Ridge National Laboratory investigates the structure and dynamics of soft materials—polymer nanocomposites, polymer electrolytes and biological macromolecules—to advance materials and technologies for energy, medicine and other applications.