Filter News

Area of Research

- (-) Clean Energy (52)

- (-) Supercomputing (3)

- Advanced Manufacturing (11)

- Biology and Environment (5)

- Building Technologies (1)

- Computational Engineering (1)

- Computer Science (4)

- Fusion Energy (5)

- Isotopes (3)

- Materials (20)

- Materials for Computing (4)

- National Security (1)

- Neutron Science (24)

- Nuclear Science and Technology (11)

- Nuclear Systems Modeling, Simulation and Validation (1)

- Transportation Systems (2)

News Topics

- (-) 3-D Printing/Advanced Manufacturing (23)

- (-) Artificial Intelligence (2)

- (-) Decarbonization (4)

- (-) Nuclear Energy (2)

- (-) Transportation (26)

- Advanced Reactors (1)

- Big Data (5)

- Bioenergy (2)

- Biology (3)

- Biomedical (5)

- Biotechnology (1)

- Buildings (13)

- Chemical Sciences (2)

- Clean Water (4)

- Climate Change (7)

- Composites (9)

- Computer Science (23)

- Coronavirus (4)

- Critical Materials (7)

- Energy Storage (22)

- Environment (17)

- Exascale Computing (1)

- Frontier (1)

- Fusion (1)

- Grid (15)

- High-Performance Computing (3)

- Hydropower (2)

- Machine Learning (3)

- Materials (13)

- Materials Science (10)

- Mathematics (1)

- Mercury (1)

- Microscopy (2)

- Nanotechnology (2)

- Net Zero (1)

- Polymers (7)

- Quantum Computing (4)

- Quantum Science (3)

- Simulation (2)

- Space Exploration (3)

- Statistics (1)

- Summit (6)

- Sustainable Energy (28)

Media Contacts

Oak Ridge National Laboratory researchers combined additive manufacturing with conventional compression molding to produce high-performance thermoplastic composites reinforced with short carbon fibers.

A team of Oak Ridge National Laboratory researchers demonstrated that an additively manufactured hot stamping die – a tool used to create car body components – cooled faster than those produced by conventional manufacturing methods.

Oak Ridge National Laboratory researchers have demonstrated that a new class of superalloys made of cobalt and nickel remains crack-free and defect-resistant in extreme heat, making them conducive for use in metal-based 3D printing applications.

Fuel economy can take a tumble when temperatures plummet, according to the Department of Energy’s 2021 Fuel Economy Guide. Compiled by researchers at Oak Ridge National Laboratory, the guide includes several tips to improve a vehicle’s fuel performance.

Algorithms developed at Oak Ridge National Laboratory can greatly enhance X-ray computed tomography images of 3D-printed metal parts, resulting in more accurate, faster scans.

If air taxis become a viable mode of transportation, Oak Ridge National Laboratory researchers have estimated they could reduce fuel consumption significantly while alleviating traffic congestion.

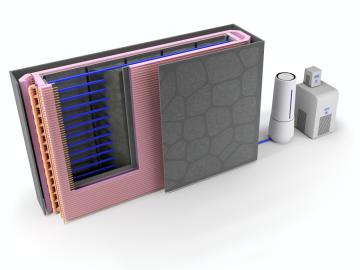

Oak Ridge National Laboratory researchers used additive manufacturing to build a first-of-its kind smart wall called EMPOWER.

Oak Ridge National Laboratory researchers have developed a machine learning model that could help predict the impact pandemics such as COVID-19 have on fuel demand in the United States.

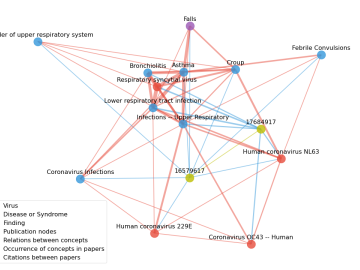

Scientists have tapped the immense power of the Summit supercomputer at Oak Ridge National Laboratory to comb through millions of medical journal articles to identify potential vaccines, drugs and effective measures that could suppress or stop the

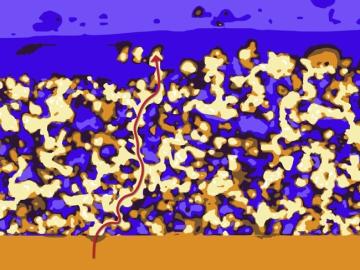

Oak Ridge National Laboratory researchers have developed a thin film, highly conductive solid-state electrolyte made of a polymer and ceramic-based composite for lithium metal batteries.