Filter News

Area of Research

- (-) Advanced Manufacturing (15)

- (-) Materials for Computing (10)

- Biological Systems (2)

- Biology and Environment (32)

- Building Technologies (7)

- Chemical and Engineering Materials (1)

- Clean Energy (152)

- Climate and Environmental Systems (4)

- Computational Biology (1)

- Computational Engineering (2)

- Computer Science (10)

- Electricity and Smart Grid (1)

- Energy Sciences (2)

- Fossil Energy (1)

- Fusion and Fission (4)

- Fusion Energy (8)

- Isotope Development and Production (1)

- Isotopes (5)

- Materials (75)

- Mathematics (1)

- National Security (8)

- Neutron Data Analysis and Visualization (2)

- Neutron Science (35)

- Nuclear Science and Technology (18)

- Nuclear Systems Modeling, Simulation and Validation (2)

- Quantum information Science (3)

- Renewable Energy (2)

- Sensors and Controls (2)

- Supercomputing (41)

- Transportation Systems (2)

News Topics

- 3-D Printing/Advanced Manufacturing (13)

- Advanced Reactors (1)

- Biomedical (1)

- Chemical Sciences (1)

- Composites (3)

- Computer Science (1)

- Coronavirus (2)

- Fusion (1)

- Materials (10)

- Materials Science (10)

- Microscopy (2)

- Nanotechnology (3)

- Neutron Science (1)

- Nuclear Energy (1)

- Polymers (1)

- Quantum Science (1)

- Space Exploration (1)

- Sustainable Energy (5)

- Transportation (1)

Media Contacts

Oak Ridge National Laboratory researchers collaborated with Iowa State University and RJ Lee Group to demonstrate a safe and effective antiviral coating for N95 masks. The coating destroys the COVID-19-causing coronavirus and could enable reuse of masks made from various fabrics.

Oak Ridge National Laboratory researchers recently used large-scale additive manufacturing with metal to produce a full-strength steel component for a wind turbine, proving the technique as a viable alternative to

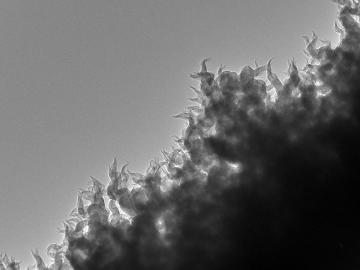

A discovery by Oak Ridge National Laboratory researchers may aid the design of materials that better manage heat.

Oak Ridge National Laboratory researchers determined that designing polymers specifically with upcycling in mind could reduce future plastic waste considerably and facilitate a circular economy where the material is used repeatedly.

Oak Ridge National Laboratory researchers have developed a novel process to manufacture extreme heat resistant carbon-carbon composites. The performance of these materials will be tested in a U.S. Navy rocket that NASA will launch this fall.

A research team at Oak Ridge National Laboratory have 3D printed a thermal protection shield, or TPS, for a capsule that will launch with the Cygnus cargo spacecraft as part of the supply mission to the International Space Station.

Oak Ridge National Laboratory researchers have developed a new catalyst for converting ethanol into C3+ olefins – the chemical

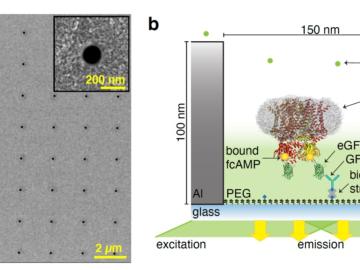

Researchers working with Oak Ridge National Laboratory developed a new method to observe how proteins, at the single-molecule level, bind with other molecules and more accurately pinpoint certain molecular behavior in complex

In a new twist to an existing award-winning ORNL technology, researchers have developed an electrocatalyst that enables water and carbon dioxide to be split and the atoms recombined to form higher weight hydrocarbons for gasoline, diesel and jet fuel.

Oak Ridge National Laboratory researchers combined additive manufacturing with conventional compression molding to produce high-performance thermoplastic composites reinforced with short carbon fibers.