Filter News

Area of Research

- (-) Materials (75)

- (-) Nuclear Science and Technology (18)

- Advanced Manufacturing (15)

- Biological Systems (2)

- Biology and Environment (32)

- Building Technologies (7)

- Chemical and Engineering Materials (1)

- Clean Energy (152)

- Climate and Environmental Systems (4)

- Computational Biology (1)

- Computational Engineering (2)

- Computer Science (10)

- Electricity and Smart Grid (1)

- Energy Sciences (2)

- Fossil Energy (1)

- Fusion and Fission (4)

- Fusion Energy (8)

- Isotope Development and Production (1)

- Isotopes (5)

- Materials for Computing (10)

- Mathematics (1)

- National Security (8)

- Neutron Data Analysis and Visualization (2)

- Neutron Science (35)

- Nuclear Systems Modeling, Simulation and Validation (2)

- Quantum information Science (3)

- Renewable Energy (2)

- Sensors and Controls (2)

- Supercomputing (41)

- Transportation Systems (2)

News Type

News Topics

- 3-D Printing/Advanced Manufacturing (6)

- Advanced Reactors (5)

- Bioenergy (1)

- Biomedical (3)

- Buildings (1)

- Chemical Sciences (4)

- Clean Water (1)

- Composites (4)

- Computer Science (1)

- Coronavirus (1)

- Critical Materials (5)

- Decarbonization (1)

- Energy Storage (7)

- Environment (1)

- Fusion (3)

- Isotopes (3)

- Materials (12)

- Materials Science (19)

- Microscopy (6)

- Molten Salt (4)

- Nanotechnology (8)

- Neutron Science (6)

- Nuclear Energy (13)

- Physics (2)

- Polymers (6)

- Quantum Computing (1)

- Quantum Science (1)

- Space Exploration (3)

- Sustainable Energy (3)

- Transportation (6)

Media Contacts

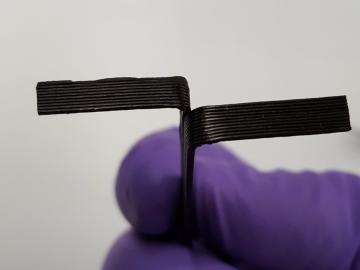

An Oak Ridge National Laboratory–led team has developed super-stretchy polymers with amazing self-healing abilities that could lead to longer-lasting consumer products.

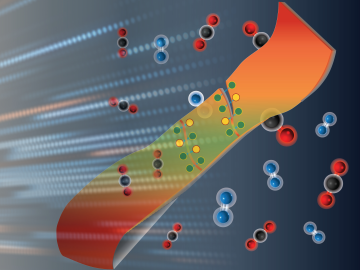

A scalable processing technique developed by Oak Ridge National Laboratory uses plant-based materials for 3D printing and offers a promising additional revenue stream for biorefineries.

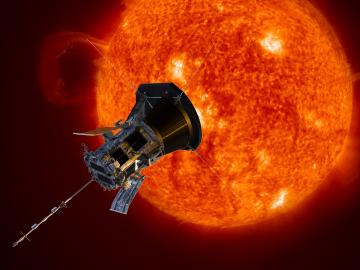

A shield assembly that protects an instrument measuring ion and electron fluxes for a NASA mission to touch the Sun was tested in extreme experimental environments at Oak Ridge National Laboratory—and passed with flying colors. Components aboard Parker Solar Probe, which will endure th...

A novel method developed at Oak Ridge National Laboratory creates supertough renewable plastic with improved manufacturability. Working with polylactic acid, a biobased plastic often used in packaging, textiles, biomedical implants and 3D printing, the research team added tiny amo...

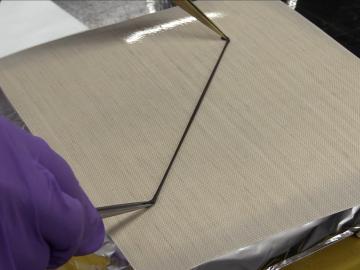

A novel approach that creates a renewable, leathery material—programmed to remember its shape—may offer a low-cost alternative to conventional conductors for applications in sensors and robotics. To make the bio-based, shape-memory material, Oak Ridge National Laboratory scientists streamlined a solvent-free process that mixes rubber with lignin—the by-product of woody plants used to make biofuels.