Filter News

Area of Research

- (-) Clean Energy (152)

- Advanced Manufacturing (15)

- Biological Systems (2)

- Biology and Environment (32)

- Building Technologies (7)

- Chemical and Engineering Materials (1)

- Climate and Environmental Systems (4)

- Computational Biology (1)

- Computational Engineering (2)

- Computer Science (10)

- Electricity and Smart Grid (1)

- Energy Sciences (2)

- Fossil Energy (1)

- Fusion and Fission (4)

- Fusion Energy (8)

- Isotope Development and Production (1)

- Isotopes (5)

- Materials (75)

- Materials for Computing (10)

- Mathematics (1)

- National Security (8)

- Neutron Data Analysis and Visualization (2)

- Neutron Science (35)

- Nuclear Science and Technology (18)

- Nuclear Systems Modeling, Simulation and Validation (2)

- Quantum information Science (3)

- Renewable Energy (2)

- Sensors and Controls (2)

- Supercomputing (41)

- Transportation Systems (2)

News Type

News Topics

- 3-D Printing/Advanced Manufacturing (23)

- Artificial Intelligence (1)

- Big Data (1)

- Bioenergy (2)

- Biology (2)

- Biomedical (1)

- Biotechnology (1)

- Buildings (13)

- Chemical Sciences (1)

- Clean Water (4)

- Climate Change (6)

- Composites (9)

- Computer Science (9)

- Coronavirus (2)

- Critical Materials (4)

- Decarbonization (4)

- Energy Storage (21)

- Environment (15)

- Grid (15)

- High-Performance Computing (1)

- Hydropower (2)

- Machine Learning (2)

- Materials (12)

- Materials Science (9)

- Mathematics (1)

- Mercury (1)

- Microscopy (2)

- Nanotechnology (1)

- Net Zero (1)

- Nuclear Energy (1)

- Polymers (5)

- Simulation (1)

- Space Exploration (2)

- Statistics (1)

- Sustainable Energy (27)

- Transportation (26)

Media Contacts

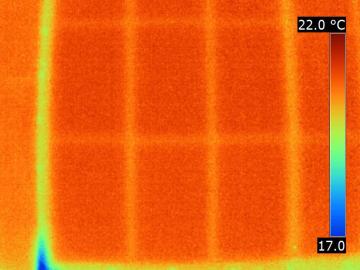

Vacuum insulation technology called modified atmosphere insulation, or MAI, could be a viable solution for improving the energy performance of buildings, based on a study by Oak Ridge National Laboratory and industry partners.

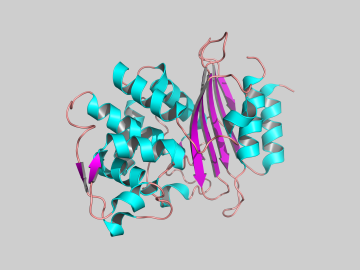

Biologists from Oak Ridge National Laboratory and the Smithsonian Environmental Research Center have confirmed that microorganisms called methanogens can transform mercury into the neurotoxin methylmercury with varying efficiency across species.

The construction industry may soon benefit from 3D printed molds to make concrete facades, promising lower cost and production time. Researchers at Oak Ridge National Laboratory are evaluating the performance of 3D printed molds used to precast concrete facades in a 42-story buildin...

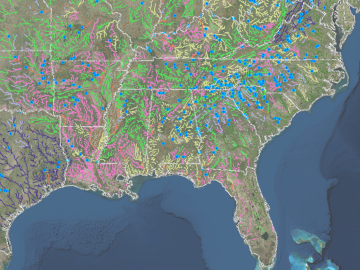

Oak Ridge National Laboratory has created new tools to better understand the nation’s waterways and identify potential sites to generate hydropower—a domestic renewable energy resource. The tools allow users such as scientists, resource agencies and industry to access information ab...

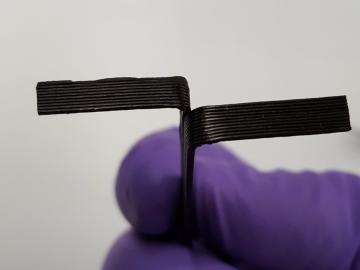

A scalable processing technique developed by Oak Ridge National Laboratory uses plant-based materials for 3D printing and offers a promising additional revenue stream for biorefineries.

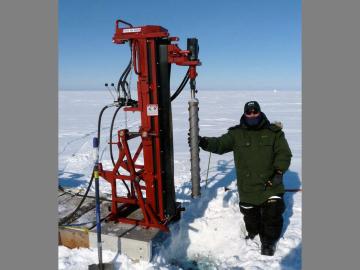

Digging into the Arctic tundra, scientists at Oak Ridge National Laboratory have uncovered new insights into how quickly microorganisms break down organic matter in warming Arctic soil—a process that releases stored carbon as carbon dioxide and methane. The team studied soil extracted...

A novel method developed at Oak Ridge National Laboratory creates supertough renewable plastic with improved manufacturability. Working with polylactic acid, a biobased plastic often used in packaging, textiles, biomedical implants and 3D printing, the research team added tiny amo...