Filter News

Area of Research

- (-) Advanced Manufacturing (22)

- (-) Building Technologies (1)

- (-) Fusion Energy (10)

- (-) Neutron Science (25)

- (-) Supercomputing (49)

- Biology and Environment (29)

- Clean Energy (156)

- Computer Science (3)

- Fuel Cycle Science and Technology (1)

- Fusion and Fission (29)

- Isotope Development and Production (1)

- Isotopes (26)

- Materials (75)

- Materials for Computing (14)

- National Security (33)

- Nuclear Science and Technology (38)

- Nuclear Systems Modeling, Simulation and Validation (1)

- Quantum information Science (9)

- Sensors and Controls (1)

- Transportation Systems (2)

News Topics

- (-) 3-D Printing/Advanced Manufacturing (28)

- (-) Biotechnology (2)

- (-) Cybersecurity (9)

- (-) Isotopes (1)

- (-) Nuclear Energy (17)

- (-) Quantum Science (29)

- (-) Security (6)

- (-) Transportation (10)

- Advanced Reactors (9)

- Artificial Intelligence (40)

- Big Data (20)

- Bioenergy (13)

- Biology (14)

- Biomedical (25)

- Buildings (7)

- Chemical Sciences (6)

- Clean Water (2)

- Climate Change (17)

- Composites (4)

- Computer Science (100)

- Coronavirus (17)

- Critical Materials (3)

- Decarbonization (7)

- Energy Storage (14)

- Environment (28)

- Exascale Computing (22)

- Fossil Energy (1)

- Frontier (29)

- Fusion (14)

- Grid (5)

- High-Performance Computing (39)

- Machine Learning (17)

- Materials (33)

- Materials Science (38)

- Mathematics (1)

- Microscopy (8)

- Molten Salt (1)

- Nanotechnology (19)

- National Security (8)

- Net Zero (1)

- Neutron Science (101)

- Partnerships (1)

- Physics (16)

- Polymers (3)

- Quantum Computing (19)

- Simulation (14)

- Software (1)

- Space Exploration (6)

- Summit (42)

- Sustainable Energy (18)

- Transformational Challenge Reactor (1)

Media Contacts

The daily traffic congestion along the streets and interstate lanes of Chattanooga could be headed the way of the horse and buggy with help from ORNL researchers.

A research team at Oak Ridge National Laboratory have 3D printed a thermal protection shield, or TPS, for a capsule that will launch with the Cygnus cargo spacecraft as part of the supply mission to the International Space Station.

Oak Ridge National Laboratory expertise in fission and fusion has come together to form a new collaboration, the Fusion Energy Reactor Models Integrator, or FERMI

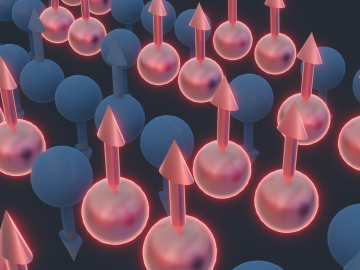

Using complementary computing calculations and neutron scattering techniques, researchers from the Department of Energy’s Oak Ridge and Lawrence Berkeley national laboratories and the University of California, Berkeley, discovered the existence of an elusive type of spin dynamics in a quantum mechanical system.

Oak Ridge National Laboratory researchers combined additive manufacturing with conventional compression molding to produce high-performance thermoplastic composites reinforced with short carbon fibers.

A team of Oak Ridge National Laboratory researchers demonstrated that an additively manufactured hot stamping die – a tool used to create car body components – cooled faster than those produced by conventional manufacturing methods.

Twenty-seven ORNL researchers Zoomed into 11 middle schools across Tennessee during the annual Engineers Week in February. East Tennessee schools throughout Oak Ridge and Roane, Sevier, Blount and Loudon counties participated, with three West Tennessee schools joining in.

For a researcher who started out in mechanical engineering with a focus on engine combustion, Martin Wissink has learned a lot about neutrons on the job

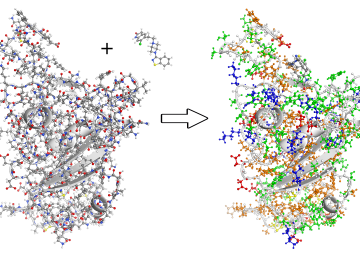

To better understand the spread of SARS-CoV-2, the virus that causes COVID-19, Oak Ridge National Laboratory researchers have harnessed the power of supercomputers to accurately model the spike protein that binds the novel coronavirus to a human cell receptor.

Oak Ridge National Laboratory researchers have demonstrated that a new class of superalloys made of cobalt and nickel remains crack-free and defect-resistant in extreme heat, making them conducive for use in metal-based 3D printing applications.