Filter News

Area of Research

- (-) Advanced Manufacturing (22)

- (-) National Security (32)

- (-) Nuclear Science and Technology (24)

- Biological Systems (2)

- Biology and Environment (105)

- Biology and Soft Matter (1)

- Building Technologies (1)

- Clean Energy (137)

- Climate and Environmental Systems (2)

- Computational Biology (2)

- Computational Engineering (2)

- Computer Science (1)

- Fusion and Fission (29)

- Fusion Energy (13)

- Isotope Development and Production (1)

- Isotopes (27)

- Materials (104)

- Materials for Computing (12)

- Mathematics (1)

- Neutron Science (39)

- Quantum information Science (4)

- Supercomputing (71)

News Topics

- (-) 3-D Printing/Advanced Manufacturing (27)

- (-) Bioenergy (5)

- (-) Biomedical (4)

- (-) Climate Change (5)

- (-) Coronavirus (3)

- (-) Cybersecurity (20)

- (-) Fusion (10)

- (-) Isotopes (5)

- (-) Physics (3)

- (-) Space Exploration (6)

- Advanced Reactors (13)

- Artificial Intelligence (13)

- Big Data (6)

- Biology (5)

- Biotechnology (1)

- Buildings (1)

- Chemical Sciences (2)

- Composites (3)

- Computer Science (22)

- Decarbonization (3)

- Energy Storage (2)

- Environment (6)

- Exascale Computing (1)

- Frontier (1)

- Grid (6)

- High-Performance Computing (4)

- Machine Learning (13)

- Materials (8)

- Materials Science (11)

- Molten Salt (4)

- Nanotechnology (1)

- National Security (34)

- Neutron Science (11)

- Nuclear Energy (41)

- Partnerships (4)

- Quantum Science (1)

- Security (11)

- Simulation (1)

- Summit (2)

- Sustainable Energy (9)

- Transformational Challenge Reactor (4)

- Transportation (2)

Media Contacts

Oak Ridge National Laboratory researchers combined additive manufacturing with conventional compression molding to produce high-performance thermoplastic composites reinforced with short carbon fibers.

A team of Oak Ridge National Laboratory researchers demonstrated that an additively manufactured hot stamping die – a tool used to create car body components – cooled faster than those produced by conventional manufacturing methods.

Oak Ridge National Laboratory researchers have demonstrated that a new class of superalloys made of cobalt and nickel remains crack-free and defect-resistant in extreme heat, making them conducive for use in metal-based 3D printing applications.

The ExOne Company, the global leader in industrial sand and metal 3D printers using binder jetting technology, announced it has reached a commercial license agreement with Oak Ridge National Laboratory to 3D print parts in aluminum-infiltrated boron carbide.

Six ORNL scientists have been elected as fellows to the American Association for the Advancement of Science, or AAAS.

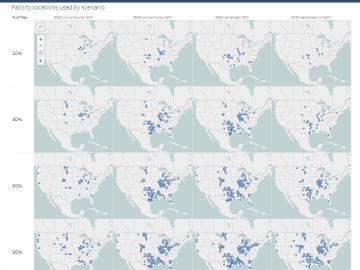

The combination of bioenergy with carbon capture and storage could cost-effectively sequester hundreds of millions of metric tons per year of carbon dioxide in the United States, making it a competitive solution for carbon management, according to a new analysis by ORNL scientists.

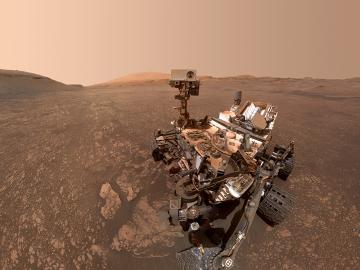

Radioactive isotopes power some of NASA’s best-known spacecraft. But predicting how radiation emitted from these isotopes might affect nearby materials is tricky

Two staff members at the Department of Energy’s Oak Ridge National Laboratory have received prestigious HENAAC and Luminary Awards from Great Minds in STEM, a nonprofit organization that focuses on promoting STEM careers in underserved

The inside of future nuclear fusion energy reactors will be among the harshest environments ever produced on Earth. What’s strong enough to protect the inside of a fusion reactor from plasma-produced heat fluxes akin to space shuttles reentering Earth’s atmosphere?

It’s a new type of nuclear reactor core. And the materials that will make it up are novel — products of Oak Ridge National Laboratory’s advanced materials and manufacturing technologies.