Filter News

Area of Research

- (-) Clean Energy (58)

- (-) Nuclear Science and Technology (38)

- Advanced Manufacturing (6)

- Biology and Environment (57)

- Biology and Soft Matter (1)

- Climate and Environmental Systems (2)

- Computational Biology (1)

- Computational Engineering (2)

- Computer Science (2)

- Electricity and Smart Grid (1)

- Fuel Cycle Science and Technology (1)

- Functional Materials for Energy (1)

- Fusion and Fission (29)

- Fusion Energy (11)

- Isotope Development and Production (1)

- Isotopes (26)

- Materials (47)

- Materials for Computing (5)

- Mathematics (1)

- National Security (30)

- Neutron Science (16)

- Nuclear Systems Modeling, Simulation and Validation (1)

- Quantum information Science (2)

- Supercomputing (91)

News Topics

- (-) Climate Change (21)

- (-) Composites (17)

- (-) Cybersecurity (9)

- (-) Frontier (2)

- (-) Isotopes (6)

- (-) Nuclear Energy (41)

- (-) Space Exploration (7)

- (-) Summit (4)

- 3-D Printing/Advanced Manufacturing (81)

- Advanced Reactors (15)

- Artificial Intelligence (8)

- Big Data (5)

- Bioenergy (26)

- Biology (11)

- Biomedical (8)

- Biotechnology (4)

- Buildings (36)

- Chemical Sciences (14)

- Clean Water (8)

- Computer Science (27)

- Coronavirus (13)

- Critical Materials (9)

- Decarbonization (33)

- Energy Storage (72)

- Environment (54)

- Exascale Computing (2)

- Fossil Energy (2)

- Fusion (9)

- Grid (40)

- High-Performance Computing (6)

- Hydropower (2)

- Machine Learning (7)

- Materials (35)

- Materials Science (29)

- Mathematics (2)

- Mercury (3)

- Microelectronics (1)

- Microscopy (8)

- Molten Salt (5)

- Nanotechnology (8)

- National Security (5)

- Net Zero (3)

- Neutron Science (15)

- Partnerships (12)

- Physics (3)

- Polymers (11)

- Quantum Science (2)

- Renewable Energy (1)

- Security (6)

- Simulation (4)

- Statistics (1)

- Sustainable Energy (69)

- Transformational Challenge Reactor (5)

- Transportation (65)

Media Contacts

Four first-of-a-kind 3D-printed fuel assembly brackets, produced at the Department of Energy’s Manufacturing Demonstration Facility at Oak Ridge National Laboratory, have been installed and are now under routine operating

A research team at Oak Ridge National Laboratory have 3D printed a thermal protection shield, or TPS, for a capsule that will launch with the Cygnus cargo spacecraft as part of the supply mission to the International Space Station.

Oak Ridge National Laboratory expertise in fission and fusion has come together to form a new collaboration, the Fusion Energy Reactor Models Integrator, or FERMI

Oak Ridge National Laboratory researchers, in collaboration with Cincinnati Inc., demonstrated the potential for using multimaterials and recycled composites in large-scale applications by 3D printing a mold that replicated a single facet of a

Oak Ridge National Laboratory was among an international team, led by Lawrence Livermore National Laboratory, who synthesized 108 elevated carbon dioxide, or CO2, experiments performed in various ecosystems to find out how much carbon is

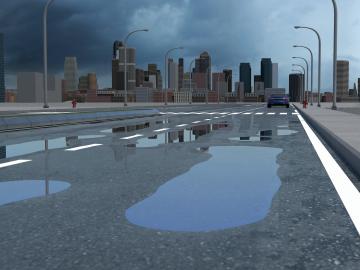

Researchers at Oak Ridge National Laboratory have identified a statistical relationship between the growth of cities and the spread of paved surfaces like roads and sidewalks. These impervious surfaces impede the flow of water into the ground, affecting the water cycle and, by extension, the climate.

Oak Ridge National Laboratory researchers combined additive manufacturing with conventional compression molding to produce high-performance thermoplastic composites reinforced with short carbon fibers.

A new tool from Oak Ridge National Laboratory can help planners, emergency responders and scientists visualize how flood waters will spread for any scenario and terrain.

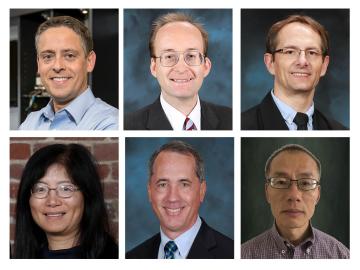

Six scientists at the Department of Energy’s Oak Ridge National Laboratory were named Battelle Distinguished Inventors, in recognition of obtaining 14 or more patents during their careers at the lab.

The University of Texas at San Antonio (UTSA) has formally launched the Cybersecurity Manufacturing Innovation Institute (CyManII), a $111 million public-private partnership.