Filter News

Area of Research

- (-) Clean Energy (166)

- (-) Materials (79)

- (-) Neutron Science (25)

- Advanced Manufacturing (8)

- Biological Systems (2)

- Biology and Environment (98)

- Biology and Soft Matter (1)

- Building Technologies (2)

- Climate and Environmental Systems (2)

- Computational Biology (1)

- Computational Engineering (2)

- Computer Science (8)

- Electricity and Smart Grid (1)

- Energy Sciences (1)

- Fuel Cycle Science and Technology (1)

- Functional Materials for Energy (1)

- Fusion and Fission (34)

- Fusion Energy (13)

- Isotope Development and Production (1)

- Isotopes (5)

- Materials for Computing (12)

- Mathematics (1)

- National Security (31)

- Nuclear Science and Technology (39)

- Nuclear Systems Modeling, Simulation and Validation (2)

- Quantum information Science (1)

- Sensors and Controls (1)

- Supercomputing (73)

- Transportation Systems (2)

News Topics

- (-) Advanced Reactors (9)

- (-) Artificial Intelligence (16)

- (-) Bioenergy (33)

- (-) Chemical Sciences (34)

- (-) Climate Change (23)

- (-) Nuclear Energy (23)

- (-) Security (8)

- (-) Sustainable Energy (71)

- (-) Transportation (71)

- 3-D Printing/Advanced Manufacturing (91)

- Big Data (8)

- Biology (17)

- Biomedical (20)

- Biotechnology (5)

- Buildings (36)

- Clean Water (11)

- Composites (19)

- Computer Science (42)

- Coronavirus (21)

- Critical Materials (19)

- Cybersecurity (11)

- Decarbonization (35)

- Energy Storage (89)

- Environment (67)

- Exascale Computing (3)

- Fossil Energy (3)

- Frontier (4)

- Fusion (8)

- Grid (41)

- High-Performance Computing (11)

- Hydropower (2)

- Irradiation (1)

- Isotopes (13)

- ITER (1)

- Machine Learning (12)

- Materials (100)

- Materials Science (99)

- Mathematics (3)

- Mercury (3)

- Microelectronics (1)

- Microscopy (29)

- Molten Salt (3)

- Nanotechnology (45)

- National Security (7)

- Net Zero (3)

- Neutron Science (107)

- Partnerships (16)

- Physics (31)

- Polymers (22)

- Quantum Computing (4)

- Quantum Science (16)

- Renewable Energy (1)

- Simulation (4)

- Space Exploration (8)

- Statistics (1)

- Summit (9)

- Transformational Challenge Reactor (5)

Media Contacts

Like most scientists, Chengping Chai is not content with the surface of things: He wants to probe beyond to learn what’s really going on. But in his case, he is literally building a map of the world beneath, using seismic and acoustic data that reveal when and where the earth moves.

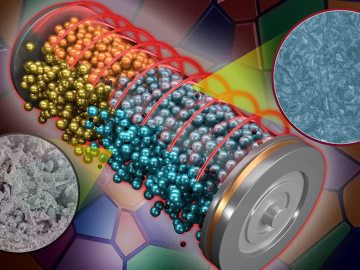

ORNL scientists found that a small tweak created big performance improvements in a type of solid-state battery, a technology considered vital to broader electric vehicle adoption.

An innovative and sustainable chemistry developed at ORNL for capturing carbon dioxide has been licensed to Holocene, a Knoxville-based startup focused on designing and building plants that remove carbon dioxide

ORNL will team up with six of eight companies that are advancing designs and research and development for fusion power plants with the mission to achieve a pilot-scale demonstration of fusion within a decade.

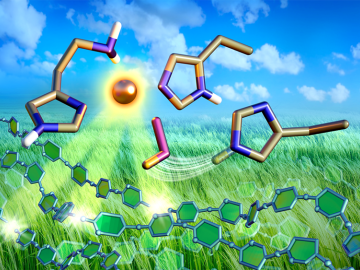

Nonfood, plant-based biofuels have potential as a green alternative to fossil fuels, but the enzymes required for production are too inefficient and costly to produce. However, new research is shining a light on enzymes from fungi that could make biofuels economically viable.

Xiao-Ying Yu, a distinguished scientist in the Materials Science and Technology Division of the Department of Energy’s Oak Ridge National Laboratory, has recently been chosen for several prominent editorial roles.

SAE International has awarded ORNL Buildings and Transportation Science Division Director Robert Wagner with the SAE Medal of Honor for his dedication and support of the organization’s mission of advancing mobility solutions.

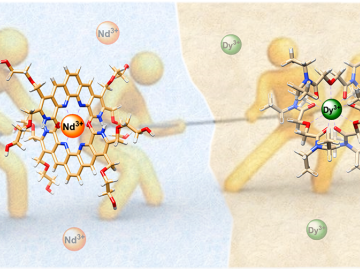

ORNL scientists combined two ligands, or metal-binding molecules, to target light and heavy lanthanides simultaneously for exceptionally efficient separation.

Oak Ridge National Laboratory researchers have developed an online resource to help consumers understand the electric vehicle tax credits available through the Inflation Reduction Act.

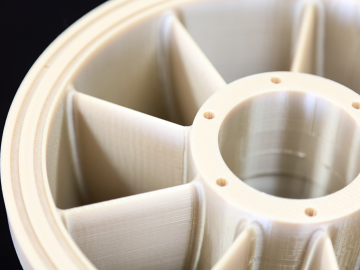

A new report published by ORNL assessed how advanced manufacturing and materials, such as 3D printing and novel component coatings, could offer solutions to modernize the existing fleet and design new approaches to hydropower.