Filter News

Area of Research

- (-) Clean Energy (14)

- Advanced Manufacturing (2)

- Biology and Environment (24)

- Computational Biology (1)

- Computational Engineering (1)

- Computer Science (6)

- Electricity and Smart Grid (1)

- Functional Materials for Energy (1)

- Fusion and Fission (23)

- Fusion Energy (13)

- Materials (17)

- National Security (14)

- Neutron Science (8)

- Nuclear Science and Technology (8)

- Supercomputing (38)

News Topics

- (-) Artificial Intelligence (8)

- (-) Biotechnology (4)

- (-) Fusion (1)

- (-) Renewable Energy (1)

- 3-D Printing/Advanced Manufacturing (78)

- Advanced Reactors (6)

- Big Data (5)

- Bioenergy (26)

- Biology (11)

- Biomedical (6)

- Buildings (36)

- Chemical Sciences (14)

- Clean Water (8)

- Climate Change (21)

- Composites (17)

- Computer Science (25)

- Coronavirus (12)

- Critical Materials (9)

- Cybersecurity (8)

- Decarbonization (33)

- Energy Storage (72)

- Environment (54)

- Exascale Computing (2)

- Fossil Energy (2)

- Frontier (2)

- Grid (40)

- High-Performance Computing (6)

- Hydropower (2)

- Isotopes (1)

- Machine Learning (7)

- Materials (35)

- Materials Science (26)

- Mathematics (2)

- Mercury (3)

- Microelectronics (1)

- Microscopy (8)

- Molten Salt (1)

- Nanotechnology (8)

- National Security (5)

- Net Zero (3)

- Neutron Science (11)

- Nuclear Energy (7)

- Partnerships (12)

- Physics (1)

- Polymers (11)

- Quantum Science (2)

- Security (6)

- Simulation (4)

- Space Exploration (3)

- Statistics (1)

- Summit (4)

- Sustainable Energy (69)

- Transformational Challenge Reactor (3)

- Transportation (65)

Media Contacts

Four scientists affiliated with ORNL were named Battelle Distinguished Inventors during the lab’s annual Innovation Awards on Dec. 1 in recognition of being granted 14 or more United States patents.

ORNL has been selected to lead an Energy Earthshot Research Center, or EERC, focused on developing chemical processes that use sustainable methods instead of burning fossil fuels to radically reduce industrial greenhouse gas emissions to stem climate change and limit the crisis of a rapidly warming planet.

Three researchers at ORNL have been named ORNL Corporate Fellows in recognition of significant career accomplishments and continued leadership in their scientific fields.

Researchers at the Department of Energy’s Oak Ridge National Laboratory and their technologies have received seven 2022 R&D 100 Awards, plus special recognition for a battery-related green technology product.

ORNL, TVA and TNECD were recognized by the Federal Laboratory Consortium for their impactful partnership that resulted in a record $2.3 billion investment by Ultium Cells, a General Motors and LG Energy Solution joint venture, to build a battery cell manufacturing plant in Spring Hill, Tennessee.

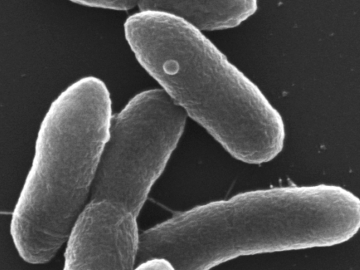

A research team led by Oak Ridge National Laboratory bioengineered a microbe to efficiently turn waste into itaconic acid, an industrial chemical used in plastics and paints.

Algorithms developed at Oak Ridge National Laboratory can greatly enhance X-ray computed tomography images of 3D-printed metal parts, resulting in more accurate, faster scans.

Six scientists at the Department of Energy’s Oak Ridge National Laboratory were named Battelle Distinguished Inventors, in recognition of obtaining 14 or more patents during their careers at the lab.

ORNL scientists have modified a single microbe to simultaneously digest five of the most abundant components of lignocellulosic biomass, a big step forward in the development of a cost-effective biochemical conversion process to turn plants into

Oak Ridge National Laboratory researchers have developed artificial intelligence software for powder bed 3D printers that assesses the quality of parts in real time, without the need for expensive characterization equipment.