Filter News

Area of Research

- (-) Advanced Manufacturing (3)

- (-) Fusion and Fission (3)

- Biology and Environment (13)

- Clean Energy (28)

- Computational Biology (1)

- Computational Engineering (1)

- Computer Science (6)

- Electricity and Smart Grid (1)

- Functional Materials for Energy (1)

- Materials (53)

- Materials for Computing (5)

- National Security (16)

- Neutron Science (101)

- Nuclear Science and Technology (5)

- Supercomputing (50)

News Topics

- (-) Artificial Intelligence (2)

- (-) Critical Materials (1)

- (-) Neutron Science (3)

- 3-D Printing/Advanced Manufacturing (25)

- Advanced Reactors (7)

- Bioenergy (2)

- Biology (1)

- Biomedical (1)

- Buildings (1)

- Chemical Sciences (4)

- Composites (4)

- Computer Science (3)

- Cybersecurity (1)

- Decarbonization (2)

- Energy Storage (4)

- Environment (2)

- Exascale Computing (1)

- Fossil Energy (1)

- Frontier (1)

- Fusion (23)

- Grid (2)

- High-Performance Computing (2)

- Isotopes (1)

- ITER (6)

- Machine Learning (1)

- Materials (7)

- Materials Science (9)

- Microscopy (1)

- Nanotechnology (1)

- Net Zero (1)

- Nuclear Energy (28)

- Partnerships (3)

- Physics (1)

- Security (2)

- Simulation (3)

- Space Exploration (2)

- Sustainable Energy (9)

- Transformational Challenge Reactor (1)

- Transportation (2)

Media Contacts

Scientists at ORNL have developed 3D-printed collimator techniques that can be used to custom design collimators that better filter out noise during different types of neutron scattering experiments

ORNL hosted its fourth Artificial Intelligence for Robust Engineering and Science, or AIRES, workshop from April 18-20. Over 100 attendees from government, academia and industry convened to identify research challenges and investment areas, carving the future of the discipline.

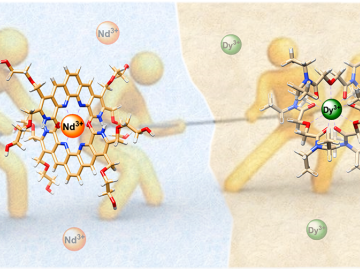

ORNL scientists combined two ligands, or metal-binding molecules, to target light and heavy lanthanides simultaneously for exceptionally efficient separation.

The Department of Energy’s Office of Science has selected five Oak Ridge National Laboratory scientists for Early Career Research Program awards.

The ExOne Company, the global leader in industrial sand and metal 3D printers using binder jetting technology, announced it has reached a commercial license agreement with Oak Ridge National Laboratory to 3D print parts in aluminum-infiltrated boron carbide.

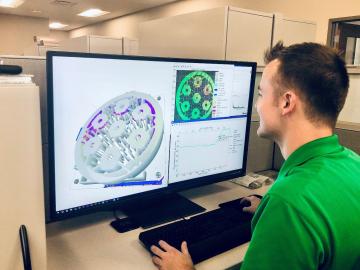

Oak Ridge National Laboratory researchers have developed artificial intelligence software for powder bed 3D printers that assesses the quality of parts in real time, without the need for expensive characterization equipment.