Filter News

Area of Research

- (-) Biology and Environment (24)

- (-) Materials (84)

- Advanced Manufacturing (5)

- Biology and Soft Matter (1)

- Clean Energy (58)

- Computer Science (1)

- Electricity and Smart Grid (1)

- Functional Materials for Energy (1)

- Fusion and Fission (6)

- Fusion Energy (2)

- Isotope Development and Production (1)

- Isotopes (2)

- Materials Characterization (1)

- Materials for Computing (16)

- Materials Under Extremes (1)

- National Security (5)

- Neutron Science (25)

- Nuclear Science and Technology (4)

- Supercomputing (20)

- Transportation Systems (2)

News Topics

- (-) Decarbonization (25)

- (-) Materials Science (82)

- 3-D Printing/Advanced Manufacturing (27)

- Advanced Reactors (4)

- Artificial Intelligence (15)

- Big Data (10)

- Bioenergy (51)

- Biology (73)

- Biomedical (20)

- Biotechnology (13)

- Buildings (5)

- Chemical Sciences (35)

- Clean Water (14)

- Climate Change (43)

- Composites (11)

- Computer Science (34)

- Coronavirus (14)

- Critical Materials (13)

- Cybersecurity (5)

- Energy Storage (37)

- Environment (100)

- Exascale Computing (6)

- Frontier (6)

- Fusion (8)

- Grid (8)

- High-Performance Computing (24)

- Hydropower (8)

- Irradiation (1)

- Isotopes (13)

- ITER (1)

- Machine Learning (11)

- Materials (78)

- Mathematics (3)

- Mercury (7)

- Microscopy (34)

- Molten Salt (3)

- Nanotechnology (42)

- National Security (5)

- Net Zero (3)

- Neutron Science (36)

- Nuclear Energy (16)

- Partnerships (12)

- Physics (30)

- Polymers (18)

- Quantum Computing (3)

- Quantum Science (11)

- Renewable Energy (2)

- Security (3)

- Simulation (15)

- Space Exploration (2)

- Summit (11)

- Sustainable Energy (42)

- Transformational Challenge Reactor (3)

- Transportation (15)

Media Contacts

Researchers at the Department of Energy’s Oak Ridge National Laboratory and their technologies have received seven 2022 R&D 100 Awards, plus special recognition for a battery-related green technology product.

ORNL Corporate Fellow and Center for Nanophase Materials Sciences researcher Bobby Sumpter has been named fellow of two scientific professional societies: the Institute of Physics and the International Association of Advanced Materials.

Chemical and environmental engineer Samarthya Bhagia is focused on achieving carbon neutrality and a circular economy by designing new plant-based materials for a range of applications from energy storage devices and sensors to environmentally friendly bioplastics.

Science has taken Melanie Mayes from Tennessee to the tropics, studying some of the most important ecosystems in the world.

ORNL researchers have developed an upcycling approach that adds value to discarded plastics for reuse in additive manufacturing, or 3D printing.

A study led by researchers at ORNL could help make materials design as customizable as point-and-click.

Tackling the climate crisis and achieving an equitable clean energy future are among the biggest challenges of our time.

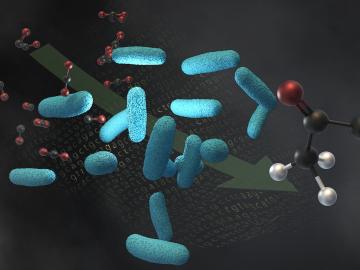

A team of scientists from LanzaTech, Northwestern University and ORNL have developed carbon capture technology that harnesses emissions from industrial processes to produce acetone and isopropanol

Muralidharan was recognized for “a highly prolific spirit of innovation in creating or facilitating outstanding inventions that have made a tangible impact on the quality of life, economic development and welfare of society.”

Energy and sustainability experts from ORNL, industry, universities and the federal government recently identified key focus areas to meet the challenge of successfully decarbonizing the agriculture sector