Filter News

Area of Research

- Advanced Manufacturing (4)

- Biology and Environment (24)

- Clean Energy (32)

- Computational Engineering (2)

- Computer Science (4)

- Electricity and Smart Grid (1)

- Functional Materials for Energy (1)

- Fusion and Fission (1)

- Materials (19)

- Materials for Computing (1)

- Mathematics (1)

- National Security (12)

- Neutron Science (6)

- Nuclear Science and Technology (4)

- Supercomputing (14)

News Topics

- (-) Clean Water (29)

- (-) Composites (26)

- (-) Machine Learning (48)

- (-) Molten Salt (8)

- 3-D Printing/Advanced Manufacturing (122)

- Advanced Reactors (34)

- Artificial Intelligence (91)

- Big Data (55)

- Bioenergy (92)

- Biology (99)

- Biomedical (58)

- Biotechnology (22)

- Buildings (57)

- Chemical Sciences (65)

- Climate Change (100)

- Computer Science (189)

- Coronavirus (46)

- Critical Materials (26)

- Cybersecurity (35)

- Decarbonization (80)

- Education (4)

- Element Discovery (1)

- Emergency (2)

- Energy Storage (109)

- Environment (195)

- Exascale Computing (37)

- Fossil Energy (6)

- Frontier (42)

- Fusion (55)

- Grid (63)

- High-Performance Computing (85)

- Hydropower (11)

- Irradiation (3)

- Isotopes (53)

- ITER (7)

- Materials (144)

- Materials Science (141)

- Mathematics (9)

- Mercury (12)

- Microelectronics (3)

- Microscopy (51)

- Nanotechnology (60)

- National Security (63)

- Net Zero (14)

- Neutron Science (131)

- Nuclear Energy (109)

- Partnerships (44)

- Physics (61)

- Polymers (33)

- Quantum Computing (34)

- Quantum Science (69)

- Renewable Energy (2)

- Security (24)

- Simulation (48)

- Software (1)

- Space Exploration (25)

- Statistics (3)

- Summit (57)

- Sustainable Energy (126)

- Transformational Challenge Reactor (7)

- Transportation (97)

Media Contacts

A research team at Oak Ridge National Laboratory have 3D printed a thermal protection shield, or TPS, for a capsule that will launch with the Cygnus cargo spacecraft as part of the supply mission to the International Space Station.

Oak Ridge National Laboratory researchers, in collaboration with Cincinnati Inc., demonstrated the potential for using multimaterials and recycled composites in large-scale applications by 3D printing a mold that replicated a single facet of a

The Department of Energy’s Oak Ridge National Laboratory has licensed its award-winning artificial intelligence software system, the Multinode Evolutionary Neural Networks for Deep Learning, to General Motors for use in vehicle technology and design.

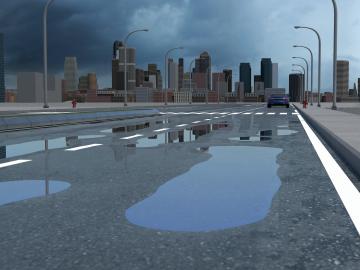

Researchers at Oak Ridge National Laboratory have identified a statistical relationship between the growth of cities and the spread of paved surfaces like roads and sidewalks. These impervious surfaces impede the flow of water into the ground, affecting the water cycle and, by extension, the climate.

Oak Ridge National Laboratory researchers combined additive manufacturing with conventional compression molding to produce high-performance thermoplastic composites reinforced with short carbon fibers.

Six scientists at the Department of Energy’s Oak Ridge National Laboratory were named Battelle Distinguished Inventors, in recognition of obtaining 14 or more patents during their careers at the lab.

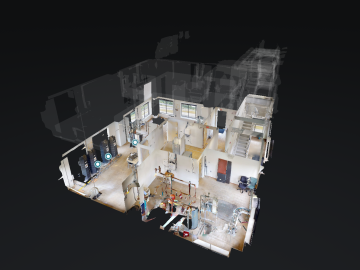

ORNL has added 10 virtual tours to its campus map, each with multiple views to show floor plans, rotating dollhouse views and 360-degree navigation. As a user travels through a map, pop-out informational windows deliver facts, videos, graphics and links to other related content.

New capabilities and equipment recently installed at the Department of Energy’s Oak Ridge National Laboratory are bringing a creek right into the lab to advance understanding of mercury pollution and accelerate solutions.

ORNL and Department of Energy officials dedicated the launch of two clean energy research initiatives that focus on the recycling and recovery of advanced manufacturing materials and on connected and

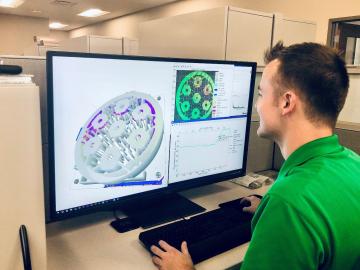

Oak Ridge National Laboratory researchers have developed artificial intelligence software for powder bed 3D printers that assesses the quality of parts in real time, without the need for expensive characterization equipment.