Filter News

Area of Research

- Advanced Manufacturing (22)

- Biology and Environment (19)

- Building Technologies (1)

- Clean Energy (82)

- Computational Engineering (1)

- Computer Science (4)

- Fusion and Fission (3)

- Fusion Energy (1)

- Materials (24)

- Materials for Computing (4)

- National Security (8)

- Neutron Science (6)

- Nuclear Science and Technology (4)

- Supercomputing (23)

News Topics

- (-) 3-D Printing/Advanced Manufacturing (116)

- (-) Big Data (50)

- (-) Education (3)

- Advanced Reactors (34)

- Artificial Intelligence (87)

- Bioenergy (88)

- Biology (96)

- Biomedical (58)

- Biotechnology (21)

- Buildings (54)

- Chemical Sciences (59)

- Clean Water (29)

- Climate Change (94)

- Composites (25)

- Computer Science (184)

- Coronavirus (46)

- Critical Materials (24)

- Cybersecurity (35)

- Decarbonization (74)

- Element Discovery (1)

- Emergency (2)

- Energy Storage (107)

- Environment (192)

- Exascale Computing (36)

- Fossil Energy (5)

- Frontier (41)

- Fusion (53)

- Grid (61)

- High-Performance Computing (83)

- Hydropower (11)

- Irradiation (3)

- Isotopes (47)

- ITER (7)

- Machine Learning (46)

- Materials (140)

- Materials Science (134)

- Mathematics (6)

- Mercury (12)

- Microelectronics (2)

- Microscopy (50)

- Molten Salt (8)

- Nanotechnology (60)

- National Security (59)

- Net Zero (12)

- Neutron Science (129)

- Nuclear Energy (105)

- Partnerships (40)

- Physics (59)

- Polymers (31)

- Quantum Computing (31)

- Quantum Science (66)

- Renewable Energy (2)

- Security (24)

- Simulation (45)

- Software (1)

- Space Exploration (24)

- Statistics (3)

- Summit (57)

- Sustainable Energy (120)

- Transformational Challenge Reactor (7)

- Transportation (93)

Media Contacts

An Oak Ridge National Laboratory-developed advanced manufacturing technology, AMCM, was recently licensed by Orbital Composites and enables the rapid production of composite-based components, which could accelerate the decarbonization of vehicles

Researchers at the Department of Energy’s Oak Ridge National Laboratory, in collaboration with NASA, are taking additive manufacturing to the final frontier by 3D printing the same kind of wheel as the design used by NASA for its robotic lunar rover, demonstrating the technology for specialized parts needed for space exploration.

The Department of Energy’s Oak Ridge National Laboratory and Tennessee State University have signed a memorandum of understanding to strengthen research cooperation and provide diverse undergraduate students enriching educational research opportunities at the lab.

ORNL and the University of Texas Rio Grande Valley, known as UTRGV, have signed a memorandum of understanding to strengthen research cooperation and establish a collaborative program for undergraduate research and education, further cementing hi

Susan Hubbard, diputada de Ciencia y Tecnología en ORNL, Can (John) Saygin, vicepresidente mayor de investigación y decano del Colegio de la Escuela de Postgrados en UTGRV, firman un Memorándum de Entendimiento comprometiéndose a fortalecer

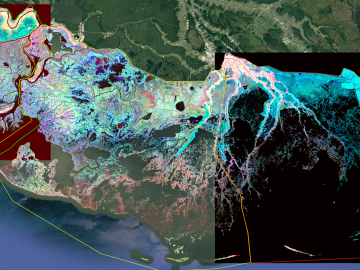

In 1993 as data managers at ORNL began compiling observations from field experiments for the National Aeronautics and Space Administration, the information fit on compact discs and was mailed to users along with printed manuals.

For 25 years, scientists at Oak Ridge National Laboratory have used their broad expertise in human health risk assessment, ecology, radiation protection, toxicology and information management to develop widely used tools and data for the U.S. Environmental Protection Agency as part of the agency’s Superfund program.

Oak Ridge National Laboratory researchers have conducted a comprehensive life cycle, cost and carbon emissions analysis on 3D-printed molds for precast concrete and determined the method is economically beneficial compared to conventional wood molds.

The Department of Energy’s Office of Science has selected three ORNL research teams to receive funding through DOE’s new Biopreparedness Research Virtual Environment initiative.

A licensing agreement between the Department of Energy’s Oak Ridge National Laboratory and research partner ZEISS will enable industrial X-ray computed tomography, or CT, to perform rapid evaluations of 3D-printed components using ORNL’s machine