Filter News

Area of Research

- Advanced Manufacturing (22)

- Biological Systems (1)

- Biology and Environment (25)

- Building Technologies (1)

- Clean Energy (82)

- Computational Biology (2)

- Computational Engineering (1)

- Fusion and Fission (4)

- Fusion Energy (1)

- Isotopes (5)

- Materials (31)

- Materials for Computing (5)

- National Security (4)

- Neutron Science (17)

- Nuclear Science and Technology (6)

- Supercomputing (40)

News Topics

- (-) 3-D Printing/Advanced Manufacturing (122)

- (-) Biomedical (58)

- (-) Quantum Computing (34)

- Advanced Reactors (34)

- Artificial Intelligence (91)

- Big Data (55)

- Bioenergy (92)

- Biology (99)

- Biotechnology (22)

- Buildings (57)

- Chemical Sciences (65)

- Clean Water (29)

- Climate Change (100)

- Composites (26)

- Computer Science (189)

- Coronavirus (46)

- Critical Materials (26)

- Cybersecurity (35)

- Decarbonization (80)

- Education (4)

- Element Discovery (1)

- Emergency (2)

- Energy Storage (109)

- Environment (195)

- Exascale Computing (37)

- Fossil Energy (6)

- Frontier (42)

- Fusion (55)

- Grid (63)

- High-Performance Computing (85)

- Hydropower (11)

- Irradiation (3)

- Isotopes (53)

- ITER (7)

- Machine Learning (48)

- Materials (144)

- Materials Science (141)

- Mathematics (8)

- Mercury (12)

- Microelectronics (3)

- Microscopy (51)

- Molten Salt (8)

- Nanotechnology (60)

- National Security (62)

- Net Zero (14)

- Neutron Science (131)

- Nuclear Energy (109)

- Partnerships (44)

- Physics (61)

- Polymers (33)

- Quantum Science (69)

- Renewable Energy (2)

- Security (24)

- Simulation (48)

- Software (1)

- Space Exploration (25)

- Statistics (3)

- Summit (57)

- Sustainable Energy (126)

- Transformational Challenge Reactor (7)

- Transportation (97)

Media Contacts

Joseph Chapman, a research scientist in quantum communications at ORNL, was given the Physical Review Applied Reviewer Excellence 2024 award for his work as a peer reviewer for the journal Physical Review Applied.

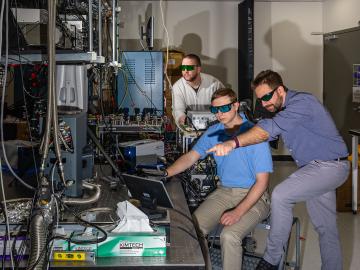

ORNL scientists are working on a project to engineer and develop a cryogenic ion trap apparatus to simulate quantum spin liquids, a key research area in materials science and neutron scattering studies.

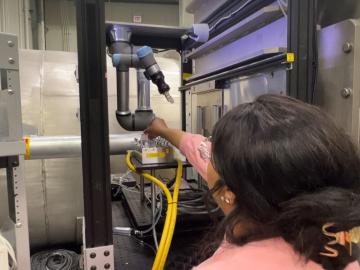

The BIO-SANS instrument, located at Oak Ridge National Laboratory’s High Flux Isotope Reactor, is the latest neutron scattering instrument to be retrofitted with state-of-the-art robotics and custom software. The sophisticated upgrade quadruples the number of samples the instrument can measure automatically and significantly reduces the need for human assistance.

Plans to unite the capabilities of two cutting-edge technological facilities funded by the Department of Energy’s Office of Science promise to usher in a new era of dynamic structural biology. Through DOE’s Integrated Research Infrastructure, or IRI, initiative, the facilities will complement each other’s technologies in the pursuit of science despite being nearly 2,500 miles apart.

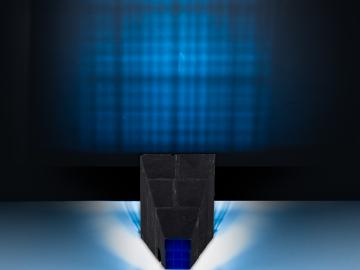

Simulations performed on the Summit supercomputer at ORNL are cutting through that time and expense by helping researchers digitally customize the ideal alloy.

Researchers simulated a key quantum state at one of the largest scales reported, with support from the Quantum Computing User Program, or QCUP, at ORNL.

Rishi Pillai and his research team from ORNL will receive a Best Paper award from the American Society of Mechanical Engineers International Gas Turbine Institute in June at the Turbo Expo 2024 in London.

The Society of Manufacturing Engineers has honored three Oak Ridge National Laboratory researchers with the 2024 SME Susan Smyth Outstanding Young Manufacturing Engineer Award.

ORNL’s Erin Webb is co-leading a new Circular Bioeconomy Systems Convergent Research Initiative focused on advancing production and use of renewable carbon from Tennessee to meet societal needs.

Scientists at ORNL have developed 3-D-printed collimator techniques that can be used to custom design collimators that better filter out noise during different types of neutron scattering experiments