Filter News

Area of Research

- Advanced Manufacturing (22)

- Biology and Environment (12)

- Building Technologies (4)

- Clean Energy (117)

- Computer Science (2)

- Electricity and Smart Grid (1)

- Fuel Cycle Science and Technology (1)

- Functional Materials for Energy (1)

- Fusion and Fission (28)

- Fusion Energy (10)

- Isotope Development and Production (1)

- Isotopes (3)

- Materials (41)

- Materials for Computing (4)

- National Security (25)

- Neutron Science (10)

- Nuclear Science and Technology (36)

- Nuclear Systems Modeling, Simulation and Validation (1)

- Quantum information Science (2)

- Supercomputing (19)

News Topics

- (-) 3-D Printing/Advanced Manufacturing (120)

- (-) Buildings (57)

- (-) Cybersecurity (35)

- (-) Nuclear Energy (107)

- Advanced Reactors (34)

- Artificial Intelligence (91)

- Big Data (53)

- Bioenergy (91)

- Biology (98)

- Biomedical (58)

- Biotechnology (22)

- Chemical Sciences (63)

- Clean Water (29)

- Climate Change (99)

- Composites (26)

- Computer Science (187)

- Coronavirus (46)

- Critical Materials (25)

- Decarbonization (79)

- Education (4)

- Element Discovery (1)

- Emergency (2)

- Energy Storage (108)

- Environment (194)

- Exascale Computing (37)

- Fossil Energy (5)

- Frontier (42)

- Fusion (54)

- Grid (62)

- High-Performance Computing (84)

- Hydropower (11)

- Irradiation (3)

- Isotopes (53)

- ITER (7)

- Machine Learning (47)

- Materials (143)

- Materials Science (139)

- Mathematics (7)

- Mercury (12)

- Microelectronics (3)

- Microscopy (51)

- Molten Salt (8)

- Nanotechnology (60)

- National Security (61)

- Net Zero (13)

- Neutron Science (131)

- Partnerships (43)

- Physics (61)

- Polymers (33)

- Quantum Computing (34)

- Quantum Science (69)

- Renewable Energy (2)

- Security (24)

- Simulation (47)

- Software (1)

- Space Exploration (25)

- Statistics (3)

- Summit (57)

- Sustainable Energy (125)

- Transformational Challenge Reactor (7)

- Transportation (97)

Media Contacts

In fiscal year 2023 — Oct. 1–Sept. 30, 2023 — Oak Ridge National Laboratory was awarded more than $8 million in technology maturation funding through the Department of Energy’s Technology Commercialization Fund, or TCF.

The heat is on at this year’s Molten Salt Reactor Workshop – where top research and industry minds are melding to advance development on molten salt technology – at ORNL.

As vehicles gain technological capabilities, car manufacturers are using an increasing number of computers and sensors to improve situational awareness and enhance the driving experience.

The Department of Energy’s Oak Ridge National Laboratory hosted the second 2023 cohort of the International Atomic Energy Agency’s Lise Meitner Programme in October.

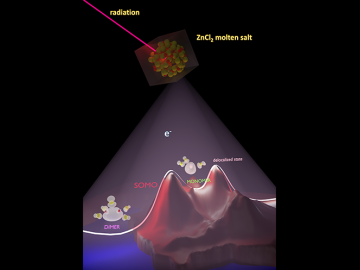

In a finding that helps elucidate how molten salts in advanced nuclear reactors might behave, scientists have shown how electrons interacting with the ions of the molten salt can form three states with different properties. Understanding these states can help predict the impact of radiation on the performance of salt-fueled reactors.

An Oak Ridge National Laboratory-developed advanced manufacturing technology, AMCM, was recently licensed by Orbital Composites and enables the rapid production of composite-based components, which could accelerate the decarbonization of vehicles

Researchers at the Department of Energy’s Oak Ridge National Laboratory, in collaboration with NASA, are taking additive manufacturing to the final frontier by 3D printing the same kind of wheel as the design used by NASA for its robotic lunar rover, demonstrating the technology for specialized parts needed for space exploration.

ORNL, a bastion of nuclear physics research for the past 80 years, is poised to strengthen its programs and service to the United States over the next decade if national recommendations of the Nuclear Science Advisory Committee, or NSAC, are enacted.

The common sounds in the background of daily life – like a refrigerator’s hum, an air conditioner’s whoosh and a heat pump’s buzz – often go unnoticed. These noises, however, are the heartbeat of a healthy building and integral for comfort and convenience.

Oak Ridge National Laboratory researchers have conducted a comprehensive life cycle, cost and carbon emissions analysis on 3D-printed molds for precast concrete and determined the method is economically beneficial compared to conventional wood molds.