Filter News

Area of Research

- Advanced Manufacturing (22)

- Biology and Environment (15)

- Building Technologies (1)

- Clean Energy (86)

- Electricity and Smart Grid (1)

- Functional Materials for Energy (1)

- Fusion and Fission (4)

- Fusion Energy (2)

- Materials (39)

- Materials for Computing (8)

- National Security (3)

- Neutron Science (8)

- Nuclear Science and Technology (4)

- Supercomputing (35)

News Topics

- (-) 3-D Printing/Advanced Manufacturing (121)

- (-) Element Discovery (1)

- (-) Frontier (42)

- (-) Polymers (33)

- Advanced Reactors (34)

- Artificial Intelligence (91)

- Big Data (53)

- Bioenergy (91)

- Biology (98)

- Biomedical (58)

- Biotechnology (22)

- Buildings (57)

- Chemical Sciences (63)

- Clean Water (29)

- Climate Change (99)

- Composites (26)

- Computer Science (187)

- Coronavirus (46)

- Critical Materials (26)

- Cybersecurity (35)

- Decarbonization (79)

- Education (4)

- Emergency (2)

- Energy Storage (108)

- Environment (194)

- Exascale Computing (37)

- Fossil Energy (5)

- Fusion (54)

- Grid (62)

- High-Performance Computing (84)

- Hydropower (11)

- Irradiation (3)

- Isotopes (53)

- ITER (7)

- Machine Learning (47)

- Materials (144)

- Materials Science (140)

- Mathematics (7)

- Mercury (12)

- Microelectronics (3)

- Microscopy (51)

- Molten Salt (8)

- Nanotechnology (60)

- National Security (61)

- Net Zero (13)

- Neutron Science (131)

- Nuclear Energy (108)

- Partnerships (44)

- Physics (61)

- Quantum Computing (34)

- Quantum Science (69)

- Renewable Energy (2)

- Security (24)

- Simulation (47)

- Software (1)

- Space Exploration (25)

- Statistics (3)

- Summit (57)

- Sustainable Energy (125)

- Transformational Challenge Reactor (7)

- Transportation (97)

Media Contacts

U.S. Secretary of Energy Jennifer Granholm visited Oak Ridge National Laboratory today to attend a groundbreaking ceremony for the U.S. Stable Isotope Production and Research Center. The facility is slated to receive $75 million in funding from the Inflation Reduction Act.

A new deep-learning framework developed at ORNL is speeding up the process of inspecting additively manufactured metal parts using X-ray computed tomography, or CT, while increasing the accuracy of the results. The reduced costs for time, labor, maintenance and energy are expected to accelerate expansion of additive manufacturing, or 3D printing.

The Earth System Grid Federation, a multi-agency initiative that gathers and distributes data for top-tier projections of the Earth’s climate, is preparing a series of upgrades.

Researchers at ORNL have developed an online tool that offers industrial plants an easier way to track and download information about their energy footprint and carbon emissions.

ORNL researchers are deploying their broad expertise in climate data and modeling to create science-based mitigation strategies for cities stressed by climate change as part of two U.S. Department of Energy Urban Integrated Field Laboratory projects.

ORNL has been selected to lead an Energy Frontier Research Center, or EFRC, focused on polymer electrolytes for next-generation energy storage devices such as fuel cells and solid-state electric vehicle batteries.

Five technologies invented by scientists at the Department of Energy’s Oak Ridge National Laboratory have been selected for targeted investment through ORNL’s Technology Innovation Program.

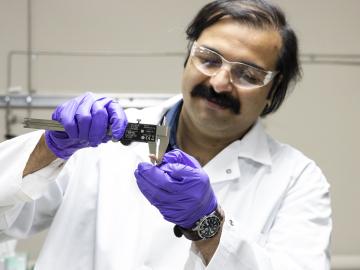

Researchers at the Department of Energy’s Oak Ridge National Laboratory and their technologies have received seven 2022 R&D 100 Awards, plus special recognition for a battery-related green technology product.

Chemical and environmental engineer Samarthya Bhagia is focused on achieving carbon neutrality and a circular economy by designing new plant-based materials for a range of applications from energy storage devices and sensors to environmentally friendly bioplastics.

ORNL researchers have developed an upcycling approach that adds value to discarded plastics for reuse in additive manufacturing, or 3D printing.