Filter News

Area of Research

- Advanced Manufacturing (22)

- Biology and Environment (11)

- Building Technologies (1)

- Clean Energy (80)

- Computer Science (3)

- Fusion and Fission (3)

- Fusion Energy (1)

- Materials (34)

- Materials for Computing (7)

- National Security (3)

- Neutron Science (13)

- Nuclear Science and Technology (4)

- Quantum information Science (9)

- Supercomputing (29)

News Topics

- (-) 3-D Printing/Advanced Manufacturing (128)

- (-) Quantum Science (73)

- Advanced Reactors (35)

- Artificial Intelligence (102)

- Big Data (62)

- Bioenergy (92)

- Biology (102)

- Biomedical (62)

- Biotechnology (24)

- Buildings (67)

- Chemical Sciences (74)

- Clean Water (31)

- Climate Change (106)

- Composites (30)

- Computer Science (199)

- Coronavirus (46)

- Critical Materials (29)

- Cybersecurity (35)

- Decarbonization (85)

- Education (5)

- Element Discovery (1)

- Emergency (2)

- Energy Storage (112)

- Environment (201)

- Exascale Computing (44)

- Fossil Energy (6)

- Frontier (46)

- Fusion (59)

- Grid (67)

- High-Performance Computing (94)

- Hydropower (11)

- Irradiation (3)

- Isotopes (57)

- ITER (7)

- Machine Learning (51)

- Materials (150)

- Materials Science (149)

- Mathematics (10)

- Mercury (12)

- Microelectronics (4)

- Microscopy (51)

- Molten Salt (9)

- Nanotechnology (60)

- National Security (73)

- Net Zero (14)

- Neutron Science (140)

- Nuclear Energy (111)

- Partnerships (51)

- Physics (64)

- Polymers (33)

- Quantum Computing (39)

- Renewable Energy (2)

- Security (26)

- Simulation (53)

- Software (1)

- Space Exploration (25)

- Statistics (3)

- Summit (61)

- Sustainable Energy (130)

- Transformational Challenge Reactor (7)

- Transportation (99)

Media Contacts

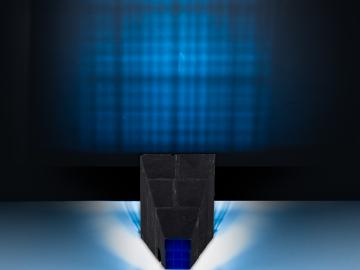

Simulations performed on the Summit supercomputer at ORNL are cutting through that time and expense by helping researchers digitally customize the ideal alloy.

The Quantum Voices series is designed to share the stories of the quantum researchers and technical experts behind the Quantum Science Center’s past, present and future accomplishments. Chengyun Hua is highlighted for this edition, talking about her role in the Quantum Science Center.

Researchers simulated a key quantum state at one of the largest scales reported, with support from the Quantum Computing User Program, or QCUP, at ORNL.

Rishi Pillai and his research team from ORNL will receive a Best Paper award from the American Society of Mechanical Engineers International Gas Turbine Institute in June at the Turbo Expo 2024 in London.

The Society of Manufacturing Engineers has honored three Oak Ridge National Laboratory researchers with the 2024 SME Susan Smyth Outstanding Young Manufacturing Engineer Award.

ORNL’s Erin Webb is co-leading a new Circular Bioeconomy Systems Convergent Research Initiative focused on advancing production and use of renewable carbon from Tennessee to meet societal needs.

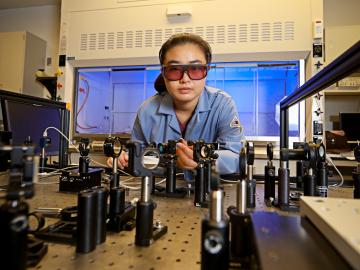

ORNL scientists have spent the past 20 years studying quantum photonic entanglement. Their partnership with colleagues at Los Alamos National Laboratory and private industry partner Qubitekk led to development of the nation’s first industry-led commercial quantum network. This type of network could ultimately help secure the nation’s power grid and other infrastructure from cyberattacks.

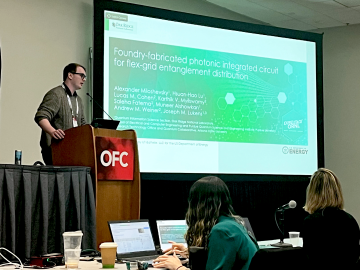

ORNL was front and center recently at one of the world’s largest optical networking conferences, the 2024 Optic Fiber Communication Conference and Exhibition, or OFC. ORNL researchers had major roles at the OFC 2024, a three-day event held in San Diego, California from March 26-28 which featured thousands of the world’s leading optical communications and networking professionals.

Scientists at ORNL have developed 3-D-printed collimator techniques that can be used to custom design collimators that better filter out noise during different types of neutron scattering experiments

ORNL scientists have determined how to avoid costly and potentially irreparable damage to large metallic parts fabricated through additive manufacturing, also known as 3D printing, that is caused by residual stress in the material.