Filter News

Area of Research

- Advanced Manufacturing (24)

- Biology and Environment (40)

- Building Technologies (3)

- Clean Energy (176)

- Computer Science (2)

- Electricity and Smart Grid (1)

- Energy Sciences (1)

- Functional Materials for Energy (1)

- Fusion and Fission (7)

- Fusion Energy (3)

- Isotope Development and Production (1)

- Isotopes (1)

- Materials (45)

- Materials for Computing (11)

- National Security (7)

- Neutron Science (13)

- Nuclear Science and Technology (5)

- Quantum information Science (1)

- Supercomputing (18)

- Transportation Systems (2)

News Topics

- (-) 3-D Printing/Advanced Manufacturing (128)

- (-) Irradiation (3)

- (-) Sustainable Energy (130)

- (-) Transportation (98)

- Advanced Reactors (34)

- Artificial Intelligence (100)

- Big Data (60)

- Bioenergy (92)

- Biology (101)

- Biomedical (61)

- Biotechnology (24)

- Buildings (65)

- Chemical Sciences (73)

- Clean Water (31)

- Climate Change (105)

- Composites (30)

- Computer Science (198)

- Coronavirus (46)

- Critical Materials (29)

- Cybersecurity (35)

- Decarbonization (85)

- Education (4)

- Element Discovery (1)

- Emergency (2)

- Energy Storage (112)

- Environment (200)

- Exascale Computing (42)

- Fossil Energy (6)

- Frontier (45)

- Fusion (58)

- Grid (66)

- High-Performance Computing (93)

- Hydropower (11)

- Isotopes (57)

- ITER (7)

- Machine Learning (50)

- Materials (147)

- Materials Science (146)

- Mathematics (9)

- Mercury (12)

- Microelectronics (4)

- Microscopy (51)

- Molten Salt (9)

- Nanotechnology (60)

- National Security (72)

- Net Zero (14)

- Neutron Science (137)

- Nuclear Energy (111)

- Partnerships (51)

- Physics (64)

- Polymers (33)

- Quantum Computing (37)

- Quantum Science (72)

- Renewable Energy (2)

- Security (25)

- Simulation (51)

- Software (1)

- Space Exploration (25)

- Statistics (3)

- Summit (59)

- Transformational Challenge Reactor (7)

Media Contacts

A new convergent manufacturing platform, developed in only five months at the Department of Energy’s Oak Ridge National Laboratory, is debuting at the International Manufacturing Technology Show, or IMTS, in Chicago, Sept. 9–12, 2024.

ORNL has partnered with Western Michigan University to advance intelligent road infrastructure through the development of new chip-enabled raised pavement markers. These innovative markers transmit lane-keeping information to passing vehicles, enhancing safety and enabling smarter driving in all weather conditions.

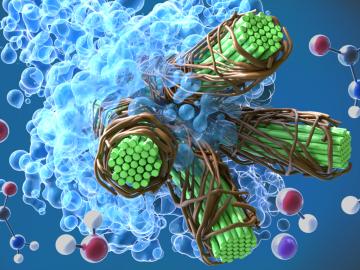

A team led by scientists at ORNL identified and demonstrated a method to process a plant-based material called nanocellulose that reduced energy needs by a whopping 21%, using simulations on the lab’s supercomputers and follow-on analysis.

ORNL is working with industry partners to develop a technique that combines 3D printing and conventional machining to produce large metal parts for clean energy applications. The project, known as Rapid Research on Universal Near Net Shape Fabrication Strategies for Expedited Runner Systems, or Rapid RUNNERS, recently received $15 million in funding from DOE.

Debjani Singh, a senior scientist at ORNL, leads the HydroSource project, which enhances hydropower research by making water data more accessible and useful. With a background in water resources, data science, and earth science, Singh applies innovative tools like AI to advance research. Her career, shaped by her early exposure to science in India, focuses on bridging research with practical applications.

Two additive manufacturing researchers from ORNL received prestigious awards from national organizations. Amy Elliott and Nadim Hmeidat, who both work in the Manufacturing Science Division, were recognized recently for their early career accomplishments.

Two ORNL teams recently completed Cohort 18 of Energy I-Corps, an immersive two-month training program where the scientists define their technology’s value propositions, conduct stakeholder discovery interviews and develop viable market pathways.

Researchers at the Department of Energy’s Oak Ridge National Laboratory and partner institutions have launched a project to develop an innovative suite of tools that will employ machine learning algorithms for more effective cybersecurity analysis of the U.S. power grid.

Brittany Rodriguez never imagined she would pursue a science career at a Department of Energy national laboratory. However, after some encouraging words from her mother, input from key mentors at the University of Texas Rio Grande Valley, or UTRGV, and a lot of hard work, Rodriguez landed at DOE’s Manufacturing Demonstration Facility, or MDF, at Oak Ridge National Laboratory.

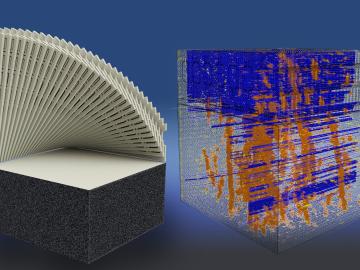

The Department of Energy’s Oak Ridge National Laboratory has publicly released a new set of additive manufacturing data that industry and researchers can use to evaluate and improve the quality of 3D-printed components. The breadth of the datasets can significantly boost efforts to verify the quality of additively manufactured parts using only information gathered during printing, without requiring expensive and time-consuming post-production analysis.