Filter News

Area of Research

- Advanced Manufacturing (22)

- Biology and Environment (15)

- Building Technologies (1)

- Clean Energy (80)

- Computer Science (1)

- Fusion and Fission (4)

- Fusion Energy (1)

- Materials (25)

- Materials for Computing (4)

- National Security (3)

- Neutron Science (6)

- Nuclear Science and Technology (4)

- Supercomputing (27)

News Topics

- (-) 3-D Printing/Advanced Manufacturing (122)

- (-) Exascale Computing (37)

- Advanced Reactors (34)

- Artificial Intelligence (91)

- Big Data (55)

- Bioenergy (92)

- Biology (99)

- Biomedical (58)

- Biotechnology (22)

- Buildings (57)

- Chemical Sciences (65)

- Clean Water (29)

- Climate Change (100)

- Composites (26)

- Computer Science (189)

- Coronavirus (46)

- Critical Materials (26)

- Cybersecurity (35)

- Decarbonization (80)

- Education (4)

- Element Discovery (1)

- Emergency (2)

- Energy Storage (109)

- Environment (195)

- Fossil Energy (6)

- Frontier (42)

- Fusion (55)

- Grid (63)

- High-Performance Computing (85)

- Hydropower (11)

- Irradiation (3)

- Isotopes (53)

- ITER (7)

- Machine Learning (48)

- Materials (144)

- Materials Science (141)

- Mathematics (9)

- Mercury (12)

- Microelectronics (3)

- Microscopy (51)

- Molten Salt (8)

- Nanotechnology (60)

- National Security (63)

- Net Zero (14)

- Neutron Science (131)

- Nuclear Energy (109)

- Partnerships (44)

- Physics (61)

- Polymers (33)

- Quantum Computing (34)

- Quantum Science (69)

- Renewable Energy (2)

- Security (24)

- Simulation (48)

- Software (1)

- Space Exploration (25)

- Statistics (3)

- Summit (57)

- Sustainable Energy (126)

- Transformational Challenge Reactor (7)

- Transportation (97)

Media Contacts

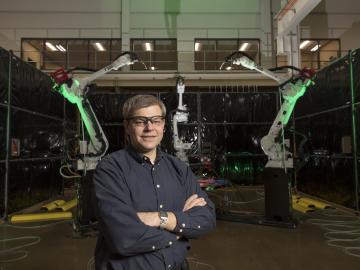

OAK RIDGE, Tenn., May 8, 2019—Oak Ridge National Laboratory and Lincoln Electric (NASDAQ: LECO) announced their continued collaboration on large-scale, robotic additive manufacturing technology at the Department of Energy’s Advanced Manufacturing InnovationXLab Summit.

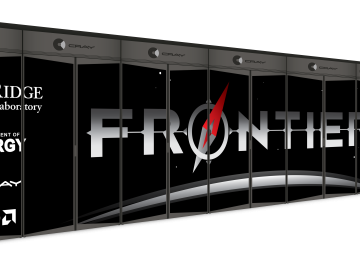

OAK RIDGE, Tenn., May 7, 2019—The U.S. Department of Energy today announced a contract with Cray Inc. to build the Frontier supercomputer at Oak Ridge National Laboratory, which is anticipated to debut in 2021 as the world’s most powerful computer with a performance of greater than 1.5 exaflops.

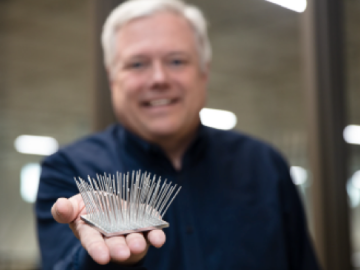

A novel additive manufacturing method developed by researchers at Oak Ridge National Laboratory could be a promising alternative for low-cost, high-quality production of large-scale metal parts with less material waste.

When Scott Smith looks at a machine tool, he thinks not about what the powerful equipment used to shape metal can do – he’s imagining what it could do with the right added parts and strategies. As ORNL’s leader for a newly formed group, Machining and Machine Tool Research, Smith will have the opportunity to do just that.

Scientists at Oak Ridge National Laboratory have developed a low-cost, printed, flexible sensor that can wrap around power cables to precisely monitor electrical loads from household appliances to support grid operations.

Alex Roschli is no stranger to finding himself in unique situations. After all, the early career researcher in ORNL’s Manufacturing Systems Research group bears a last name that only 29 other people share in the United States, and he’s certain he’s the only Roschli (a moniker that hails from Switzerland) with the first name Alex.

A residential and commercial tower under development in Brooklyn that is changing the New York City skyline has its roots in research at the Department of Energy’s Oak Ridge National Laboratory.

Scientists at the Department of Energy’s Oak Ridge National Laboratory have created a recipe for a renewable 3D printing feedstock that could spur a profitable new use for an intractable biorefinery byproduct: lignin.

Two leaders in US manufacturing innovation, Thomas Kurfess and Scott Smith, are joining the Department of Energy’s Oak Ridge National Laboratory to support its pioneering research in advanced manufacturing.