Filter News

Area of Research

News Topics

- (-) Composites (29)

- (-) ITER (7)

- (-) Mercury (12)

- (-) Molten Salt (8)

- 3-D Printing/Advanced Manufacturing (125)

- Advanced Reactors (34)

- Artificial Intelligence (95)

- Big Data (58)

- Bioenergy (92)

- Biology (100)

- Biomedical (59)

- Biotechnology (23)

- Buildings (59)

- Chemical Sciences (67)

- Clean Water (30)

- Climate Change (101)

- Computer Science (194)

- Coronavirus (46)

- Critical Materials (28)

- Cybersecurity (35)

- Decarbonization (81)

- Education (4)

- Element Discovery (1)

- Emergency (2)

- Energy Storage (110)

- Environment (197)

- Exascale Computing (39)

- Fossil Energy (6)

- Frontier (44)

- Fusion (55)

- Grid (65)

- High-Performance Computing (88)

- Hydropower (11)

- Irradiation (3)

- Isotopes (53)

- Machine Learning (48)

- Materials (144)

- Materials Science (143)

- Mathematics (9)

- Microelectronics (3)

- Microscopy (51)

- Nanotechnology (60)

- National Security (66)

- Net Zero (14)

- Neutron Science (131)

- Nuclear Energy (109)

- Partnerships (48)

- Physics (63)

- Polymers (33)

- Quantum Computing (35)

- Quantum Science (69)

- Renewable Energy (2)

- Security (24)

- Simulation (49)

- Software (1)

- Space Exploration (25)

- Statistics (3)

- Summit (59)

- Sustainable Energy (129)

- Transformational Challenge Reactor (7)

- Transportation (97)

Media Contacts

Researchers at ORNL are extending the boundaries of composite-based materials used in additive manufacturing, or AM. ORNL is working with industrial partners who are exploring AM, also known as 3D printing, as a path to higher production levels and fewer supply chain interruptions.

In fiscal year 2023 — Oct. 1–Sept. 30, 2023 — Oak Ridge National Laboratory was awarded more than $8 million in technology maturation funding through the Department of Energy’s Technology Commercialization Fund, or TCF.

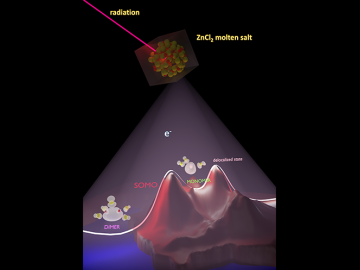

In a finding that helps elucidate how molten salts in advanced nuclear reactors might behave, scientists have shown how electrons interacting with the ions of the molten salt can form three states with different properties. Understanding these states can help predict the impact of radiation on the performance of salt-fueled reactors.

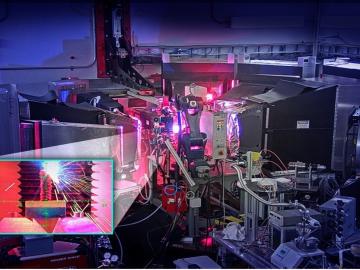

Technologies developed by researchers at ORNL have received six 2023 R&D 100 Awards.

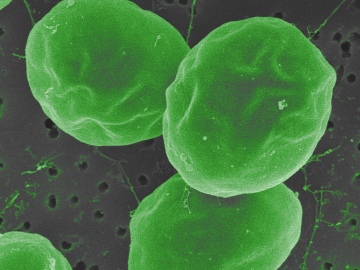

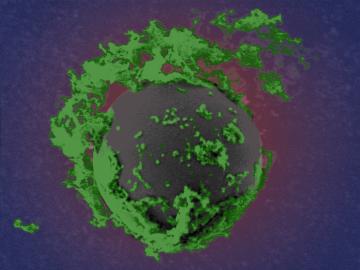

In the search for ways to fight methylmercury in global waterways, scientists at Oak Ridge National Laboratory discovered that some forms of phytoplankton are good at degrading the potent neurotoxin.

When reading the novel Jurassic Park as a teenager, Jerry Parks found the passages about gene sequencing and supercomputers fascinating, but never imagined he might someday pursue such futuristic-sounding science.

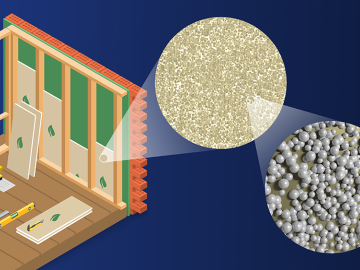

Scientists at ORNL developed a competitive, eco-friendly alternative made without harmful blowing agents.

The presence of minerals called ash in plants makes little difference to the fitness of new naturally derived compound materials designed for additive manufacturing, an Oak Ridge National Laboratory-led team found.

Oak Ridge National Laboratory scientists designed a recyclable polymer for carbon-fiber composites to enable circular manufacturing of parts that boost energy efficiency in automotive, wind power and aerospace applications.

Chemical and environmental engineer Samarthya Bhagia is focused on achieving carbon neutrality and a circular economy by designing new plant-based materials for a range of applications from energy storage devices and sensors to environmentally friendly bioplastics.