Filter News

Area of Research

News Topics

- (-) Composites (26)

- (-) Exascale Computing (37)

- (-) Quantum Computing (34)

- 3-D Printing/Advanced Manufacturing (122)

- Advanced Reactors (34)

- Artificial Intelligence (91)

- Big Data (55)

- Bioenergy (92)

- Biology (99)

- Biomedical (58)

- Biotechnology (22)

- Buildings (57)

- Chemical Sciences (65)

- Clean Water (29)

- Climate Change (100)

- Computer Science (189)

- Coronavirus (46)

- Critical Materials (26)

- Cybersecurity (35)

- Decarbonization (80)

- Education (4)

- Element Discovery (1)

- Emergency (2)

- Energy Storage (109)

- Environment (195)

- Fossil Energy (6)

- Frontier (42)

- Fusion (55)

- Grid (63)

- High-Performance Computing (85)

- Hydropower (11)

- Irradiation (3)

- Isotopes (53)

- ITER (7)

- Machine Learning (48)

- Materials (144)

- Materials Science (141)

- Mathematics (8)

- Mercury (12)

- Microelectronics (3)

- Microscopy (51)

- Molten Salt (8)

- Nanotechnology (60)

- National Security (62)

- Net Zero (14)

- Neutron Science (131)

- Nuclear Energy (109)

- Partnerships (44)

- Physics (61)

- Polymers (33)

- Quantum Science (69)

- Renewable Energy (2)

- Security (24)

- Simulation (48)

- Software (1)

- Space Exploration (25)

- Statistics (3)

- Summit (57)

- Sustainable Energy (126)

- Transformational Challenge Reactor (7)

- Transportation (97)

Media Contacts

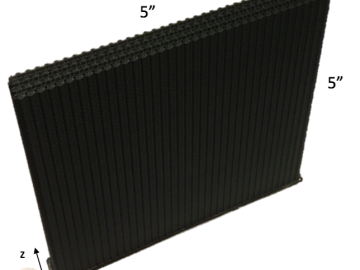

Oak Ridge National Laboratory researchers combined additive manufacturing with conventional compression molding to produce high-performance thermoplastic composites reinforced with short carbon fibers.

To better understand the spread of SARS-CoV-2, the virus that causes COVID-19, Oak Ridge National Laboratory researchers have harnessed the power of supercomputers to accurately model the spike protein that binds the novel coronavirus to a human cell receptor.

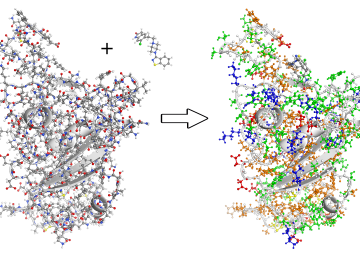

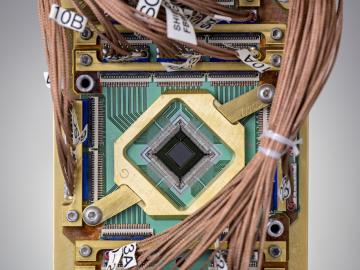

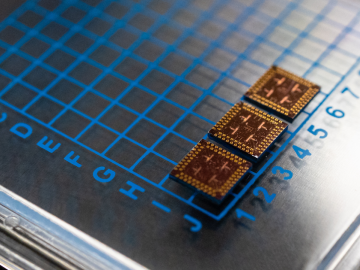

A multi-institutional team became the first to generate accurate results from materials science simulations on a quantum computer that can be verified with neutron scattering experiments and other practical techniques.

ORNL and Department of Energy officials dedicated the launch of two clean energy research initiatives that focus on the recycling and recovery of advanced manufacturing materials and on connected and

A team of scientists led by Oak Ridge National Laboratory found that while all regions of the country can expect an earlier start to the growing season as temperatures rise, the trend is likely to become more variable year-over-year in hotter regions.

Scientists at have experimentally demonstrated a novel cryogenic, or low temperature, memory cell circuit design based on coupled arrays of Josephson junctions, a technology that may be faster and more energy efficient than existing memory devices.

Researchers across the scientific spectrum crave data, as it is essential to understanding the natural world and, by extension, accelerating scientific progress.

For nearly three decades, scientists and engineers across the globe have worked on the Square Kilometre Array (SKA), a project focused on designing and building the world’s largest radio telescope. Although the SKA will collect enormous amounts of precise astronomical data in record time, scientific breakthroughs will only be possible with systems able to efficiently process that data.

ORNL and The University of Toledo have entered into a memorandum of understanding for collaborative research.

A team including Oak Ridge National Laboratory and University of Tennessee researchers demonstrated a novel 3D printing approach called Z-pinning that can increase the material’s strength and toughness by more than three and a half times compared to conventional additive manufacturing processes.