Filter News

Area of Research

- Advanced Manufacturing (5)

- Biology and Environment (12)

- Clean Energy (38)

- Computer Science (1)

- Electricity and Smart Grid (1)

- Functional Materials for Energy (1)

- Fusion and Fission (8)

- Fusion Energy (2)

- Isotope Development and Production (1)

- Isotopes (25)

- Materials (99)

- Materials Characterization (1)

- Materials for Computing (16)

- Materials Under Extremes (1)

- National Security (7)

- Neutron Science (23)

- Nuclear Science and Technology (7)

- Supercomputing (18)

- Transportation Systems (1)

News Topics

- (-) Isotopes (46)

- (-) Materials Science (134)

- (-) Partnerships (40)

- 3-D Printing/Advanced Manufacturing (116)

- Advanced Reactors (33)

- Artificial Intelligence (84)

- Big Data (50)

- Bioenergy (88)

- Biology (96)

- Biomedical (58)

- Biotechnology (21)

- Buildings (54)

- Chemical Sciences (59)

- Clean Water (29)

- Climate Change (94)

- Composites (25)

- Computer Science (182)

- Coronavirus (46)

- Critical Materials (24)

- Cybersecurity (35)

- Decarbonization (73)

- Education (3)

- Element Discovery (1)

- Emergency (2)

- Energy Storage (106)

- Environment (192)

- Exascale Computing (34)

- Fossil Energy (5)

- Frontier (39)

- Fusion (52)

- Grid (59)

- High-Performance Computing (82)

- Hydropower (11)

- Irradiation (3)

- ITER (7)

- Machine Learning (44)

- Materials (140)

- Mathematics (6)

- Mercury (12)

- Microelectronics (2)

- Microscopy (50)

- Molten Salt (8)

- Nanotechnology (60)

- National Security (56)

- Net Zero (11)

- Neutron Science (129)

- Nuclear Energy (103)

- Physics (58)

- Polymers (31)

- Quantum Computing (28)

- Quantum Science (65)

- Renewable Energy (2)

- Security (23)

- Simulation (43)

- Software (1)

- Space Exploration (24)

- Statistics (3)

- Summit (57)

- Sustainable Energy (119)

- Transformational Challenge Reactor (7)

- Transportation (93)

Media Contacts

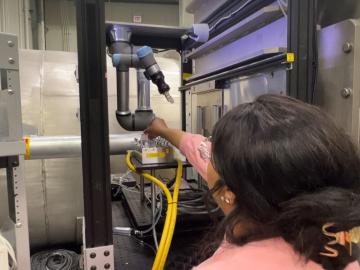

The BIO-SANS instrument, located at Oak Ridge National Laboratory’s High Flux Isotope Reactor, is the latest neutron scattering instrument to be retrofitted with state-of-the-art robotics and custom software. The sophisticated upgrade quadruples the number of samples the instrument can measure automatically and significantly reduces the need for human assistance.

A collection of seven technologies for lithium recovery developed by scientists from ORNL has been licensed to Element3, a Texas-based company focused on extracting lithium from wastewater produced by oil and gas production.

The new section of tunnel will provide the turning and connecting point for the accelerator beamline between the existing particle accelerator at ORNL’s Spallation Neutron Source and the planned Second Target Station, or STS. When complete, the PPU project will increase accelerator power up to 2.8 megawatts from its current record-breaking 1.7 megawatts of beam power.

Scientists at the Department of Energy’s Oak Ridge National Laboratory have developed lubricant additives that protect both water turbine equipment and the surrounding environment.

The U.S. Environmental Protection Agency has approved the registration and use of a renewable gasoline blendstock developed by Vertimass LLC and ORNL that can significantly reduce the emissions profile of vehicles when added to conventional fuels.

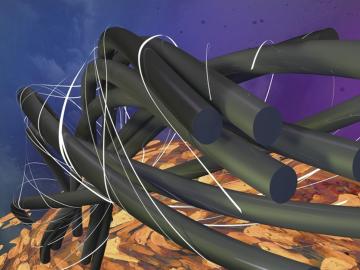

Scientists at ORNL have developed a method that demonstrates how fiber-reinforced polymer composite materials used in the automotive, aerospace and renewable energy industries can be made stronger and tougher to better withstand mechanical or structural stresses over time.

ORNL’s Omer Onar and Mostak Mohammad will present on ORNL's wireless charging technology in DOE’s Office of Technology Transitions National Lab Discovery Series Tuesday, April 30.

ORNL’s Erin Webb is co-leading a new Circular Bioeconomy Systems Convergent Research Initiative focused on advancing production and use of renewable carbon from Tennessee to meet societal needs.

Shift Thermal, a member of Innovation Crossroads’ first cohort of fellows, is commercializing advanced ice thermal energy storage for HVAC, shifting the cooling process to be more sustainable, cost-effective and resilient. Shift Thermal wants to enable a lower-cost, more-efficient thermal energy storage method to provide long-duration resilient cooling when the electric grid is down.

Three ORNL intellectual property projects with industry partners have advanced in DOE's Office of Technology Transitions Making Advanced Technology Commercialization Harmonized, or Lab MATCH, prize, which encourages entrepreneurs to find actionable pathways that bring lab-developed intellectual property to market.