Filter News

Area of Research

- Advanced Manufacturing (6)

- Biology and Environment (17)

- Building Technologies (3)

- Clean Energy (67)

- Computer Science (2)

- Electricity and Smart Grid (1)

- Functional Materials for Energy (2)

- Fusion and Fission (3)

- Fusion Energy (1)

- Isotopes (4)

- Materials (80)

- Materials Characterization (2)

- Materials for Computing (10)

- Materials Under Extremes (1)

- National Security (4)

- Neutron Science (14)

- Nuclear Science and Technology (4)

- Supercomputing (39)

News Topics

- (-) Buildings (59)

- (-) Exascale Computing (39)

- (-) Materials (144)

- (-) Molten Salt (8)

- 3-D Printing/Advanced Manufacturing (125)

- Advanced Reactors (34)

- Artificial Intelligence (95)

- Big Data (58)

- Bioenergy (92)

- Biology (100)

- Biomedical (59)

- Biotechnology (23)

- Chemical Sciences (67)

- Clean Water (30)

- Climate Change (101)

- Composites (29)

- Computer Science (194)

- Coronavirus (46)

- Critical Materials (28)

- Cybersecurity (35)

- Decarbonization (81)

- Education (4)

- Element Discovery (1)

- Emergency (2)

- Energy Storage (110)

- Environment (197)

- Fossil Energy (6)

- Frontier (44)

- Fusion (55)

- Grid (65)

- High-Performance Computing (88)

- Hydropower (11)

- Irradiation (3)

- Isotopes (53)

- ITER (7)

- Machine Learning (48)

- Materials Science (143)

- Mathematics (9)

- Mercury (12)

- Microelectronics (3)

- Microscopy (51)

- Nanotechnology (60)

- National Security (66)

- Net Zero (14)

- Neutron Science (131)

- Nuclear Energy (109)

- Partnerships (48)

- Physics (63)

- Polymers (33)

- Quantum Computing (35)

- Quantum Science (69)

- Renewable Energy (2)

- Security (24)

- Simulation (49)

- Software (1)

- Space Exploration (25)

- Statistics (3)

- Summit (59)

- Sustainable Energy (129)

- Transformational Challenge Reactor (7)

- Transportation (97)

Media Contacts

Seven entrepreneurs comprise the next cohort of Innovation Crossroads, a DOE Lab-Embedded Entrepreneurship Program node based at ORNL. The program provides energy-related startup founders from across the nation with access to ORNL’s unique scientific resources and capabilities, as well as connect them with experts, mentors and networks to accelerate their efforts to take their world-changing ideas to the marketplace.

Five researchers at the Department of Energy’s Oak Ridge National Laboratory recently completed an eight-week pilot commercialization coaching program as part of Safari, a program funded by DOE’s Office of Technology Transitions, or OTT, Practices to Accelerate the Commercialization of Technologies, or PACT.

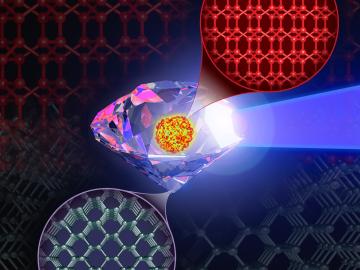

The world’s fastest supercomputer helped researchers simulate synthesizing a material harder and tougher than a diamond — or any other substance on Earth. The study used Frontier to predict the likeliest strategy to synthesize such a material, thought to exist so far only within the interiors of giant exoplanets, or planets beyond our solar system.

Researchers conduct largest, most accurate molecular dynamics simulations to date of two million correlated electrons using Frontier, the world’s fastest supercomputer. The simulation, which exceed an exaflop using full double precision, is 1,000 times greater in size and speed than any quantum chemistry simulation of it's kind.

Advanced materials research to enable energy-efficient, cost-competitive and environmentally friendly technologies for the United States and Japan is the goal of a memorandum of understanding, or MOU, between the Department of Energy’s Oak Ridge National Laboratory and Japan’s National Institute of Materials Science.

Researchers at Oak Ridge National Laboratory have developed free data sets to estimate how much energy any building in the contiguous U.S. will use in 2100. These data sets provide planners a way to anticipate future energy needs as the climate changes.

Researchers at ORNL and the University of Maine have designed and 3D-printed a single-piece, recyclable natural-material floor panel tested to be strong enough to replace construction materials like steel.

Building innovations from ORNL will be on display in Washington, D.C. on the National Mall June 7 to June 9, 2024, during the U.S. Department of Housing and Urban Development’s Innovation Housing Showcase. For the first time, ORNL’s real-time building evaluator was demonstrated outside of a laboratory setting and deployed for building construction.

John Lagergren, a staff scientist in Oak Ridge National Laboratory’s Plant Systems Biology group, is using his expertise in applied math and machine learning to develop neural networks to quickly analyze the vast amounts of data on plant traits amassed at ORNL’s Advanced Plant Phenotyping Laboratory.

ORNL researchers used electron-beam additive manufacturing to 3D-print the first complex, defect-free tungsten parts with complex geometries.