Filter News

Area of Research

- Advanced Manufacturing (3)

- Biological Systems (1)

- Biology and Environment (31)

- Clean Energy (33)

- Computer Science (1)

- Fusion and Fission (17)

- Fusion Energy (5)

- Materials (21)

- Materials for Computing (1)

- National Security (10)

- Neutron Science (8)

- Nuclear Science and Technology (9)

- Quantum information Science (1)

- Supercomputing (15)

News Type

News Topics

- (-) 3-D Printing/Advanced Manufacturing (43)

- (-) Bioenergy (51)

- (-) Composites (8)

- (-) Fusion (31)

- (-) Machine Learning (23)

- (-) Molten Salt (1)

- (-) Physics (31)

- Advanced Reactors (8)

- Artificial Intelligence (51)

- Big Data (29)

- Biology (60)

- Biomedical (31)

- Biotechnology (12)

- Buildings (23)

- Chemical Sciences (27)

- Clean Water (15)

- Climate Change (52)

- Computer Science (89)

- Coronavirus (17)

- Critical Materials (5)

- Cybersecurity (14)

- Decarbonization (47)

- Education (2)

- Emergency (2)

- Energy Storage (30)

- Environment (105)

- Exascale Computing (29)

- Fossil Energy (4)

- Frontier (26)

- Grid (26)

- High-Performance Computing (48)

- Hydropower (5)

- Isotopes (31)

- ITER (2)

- Materials (44)

- Materials Science (47)

- Mathematics (7)

- Mercury (7)

- Microelectronics (3)

- Microscopy (20)

- Nanotechnology (16)

- National Security (47)

- Net Zero (8)

- Neutron Science (51)

- Nuclear Energy (56)

- Partnerships (21)

- Polymers (8)

- Quantum Computing (22)

- Quantum Science (32)

- Renewable Energy (1)

- Security (12)

- Simulation (33)

- Software (1)

- Space Exploration (12)

- Statistics (1)

- Summit (31)

- Sustainable Energy (48)

- Transformational Challenge Reactor (3)

- Transportation (27)

Media Contacts

A new convergent manufacturing platform, developed in only five months at the Department of Energy’s Oak Ridge National Laboratory, is debuting at the International Manufacturing Technology Show, or IMTS, in Chicago, Sept. 9–12, 2024.

As a mechanical engineer in building envelope materials research at ORNL, Bryan Maldonado sees opportunities to apply his scientific expertise virtually everywhere he goes, from coast to coast. As an expert in understanding how complex systems operate, he’s using machine learning methods to control the process and ultimately optimize performance.

Nuclear physicists at the Department of Energy’s Oak Ridge National Laboratory recently used Frontier, the world’s most powerful supercomputer, to calculate the magnetic properties of calcium-48’s atomic nucleus.

Scientists have determined that a rare element found in some of the oldest solids in the solar system, such as meteorites, and previously thought to have been forged in supernova explosions, actually predate such cosmic events, challenging long-held theories about its origin.

Two additive manufacturing researchers from ORNL received prestigious awards from national organizations. Amy Elliott and Nadim Hmeidat, who both work in the Manufacturing Science Division, were recognized recently for their early career accomplishments.

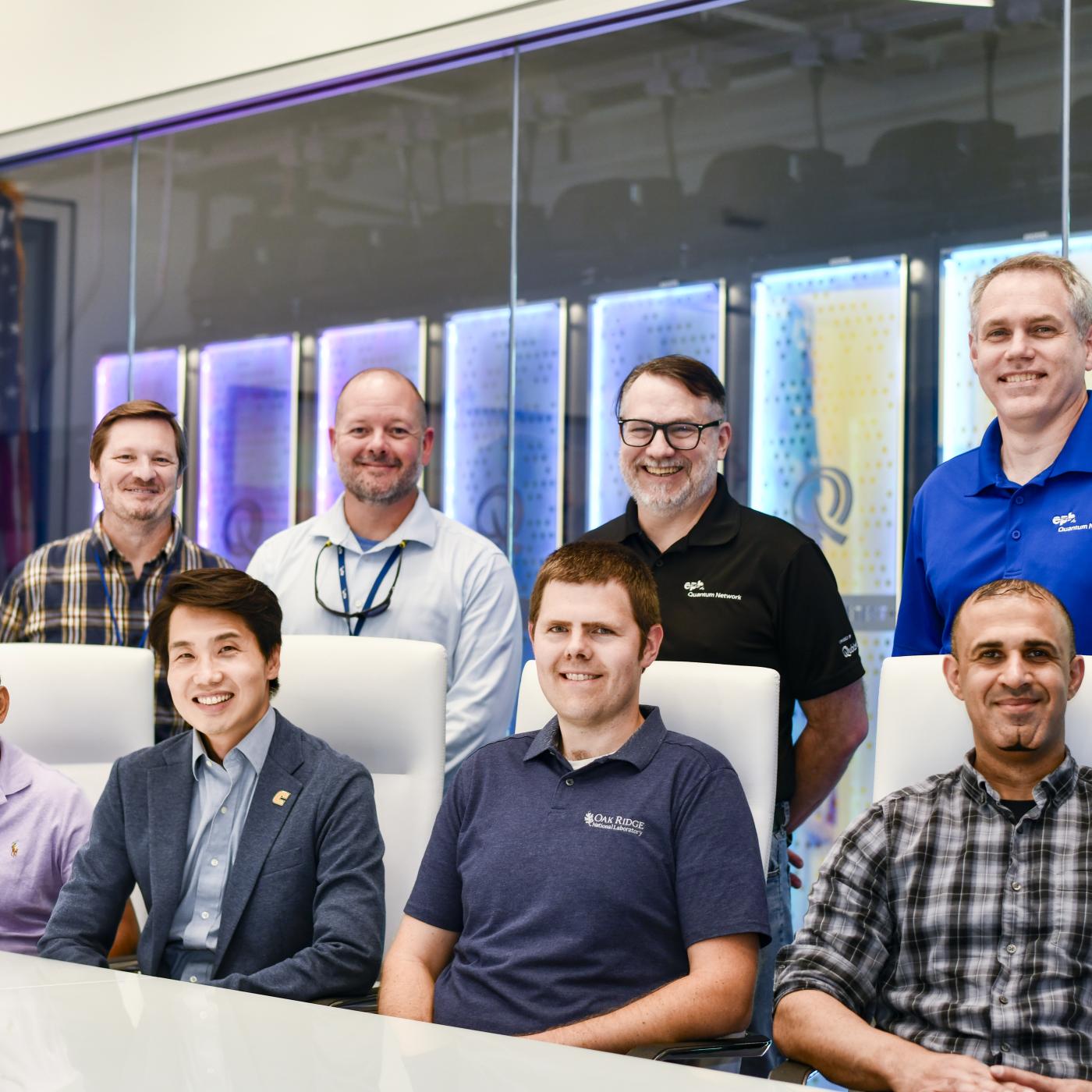

Two ORNL teams recently completed Cohort 18 of Energy I-Corps, an immersive two-month training program where the scientists define their technology’s value propositions, conduct stakeholder discovery interviews and develop viable market pathways.

Brittany Rodriguez never imagined she would pursue a science career at a Department of Energy national laboratory. However, after some encouraging words from her mother, input from key mentors at the University of Texas Rio Grande Valley, or UTRGV, and a lot of hard work, Rodriguez landed at DOE’s Manufacturing Demonstration Facility, or MDF, at Oak Ridge National Laboratory.

The Department of Energy’s Oak Ridge National Laboratory has publicly released a new set of additive manufacturing data that industry and researchers can use to evaluate and improve the quality of 3D-printed components. The breadth of the datasets can significantly boost efforts to verify the quality of additively manufactured parts using only information gathered during printing, without requiring expensive and time-consuming post-production analysis.

Researchers conduct largest, most accurate molecular dynamics simulations to date of two million correlated electrons using Frontier, the world’s fastest supercomputer. The simulation, which exceed an exaflop using full double precision, is 1,000 times greater in size and speed than any quantum chemistry simulation of it's kind.

Oak Ridge National Laboratory has named Troy A. Carter director of the Fusion Energy Division in ORNL’s Fusion and Fission Energy and Science Directorate, or FFESD.