Filter News

Area of Research

- Advanced Manufacturing (3)

- Biological Systems (1)

- Biology and Environment (40)

- Biology and Soft Matter (1)

- Clean Energy (40)

- Climate and Environmental Systems (1)

- Computational Biology (1)

- Fusion and Fission (5)

- Isotopes (17)

- Materials (19)

- Materials for Computing (2)

- National Security (13)

- Neutron Science (9)

- Nuclear Science and Technology (5)

- Quantum information Science (2)

- Supercomputing (35)

News Type

News Topics

- (-) 3-D Printing/Advanced Manufacturing (39)

- (-) Biomedical (28)

- (-) Climate Change (50)

- (-) Composites (6)

- (-) Cybersecurity (14)

- (-) Frontier (24)

- (-) Isotopes (27)

- (-) Microscopy (20)

- (-) Molten Salt (1)

- (-) Space Exploration (12)

- Advanced Reactors (8)

- Artificial Intelligence (46)

- Big Data (24)

- Bioenergy (51)

- Biology (59)

- Biotechnology (11)

- Buildings (19)

- Chemical Sciences (24)

- Clean Water (14)

- Computer Science (83)

- Coronavirus (17)

- Critical Materials (2)

- Decarbonization (46)

- Education (1)

- Emergency (2)

- Energy Storage (29)

- Environment (104)

- Exascale Computing (25)

- Fossil Energy (4)

- Fusion (31)

- Grid (23)

- High-Performance Computing (44)

- Hydropower (5)

- ITER (2)

- Machine Learning (22)

- Materials (43)

- Materials Science (45)

- Mathematics (7)

- Mercury (7)

- Microelectronics (2)

- Nanotechnology (16)

- National Security (37)

- Net Zero (8)

- Neutron Science (47)

- Nuclear Energy (55)

- Partnerships (16)

- Physics (28)

- Polymers (8)

- Quantum Computing (20)

- Quantum Science (30)

- Renewable Energy (1)

- Security (11)

- Simulation (31)

- Software (1)

- Statistics (1)

- Summit (30)

- Sustainable Energy (44)

- Transformational Challenge Reactor (3)

- Transportation (27)

Media Contacts

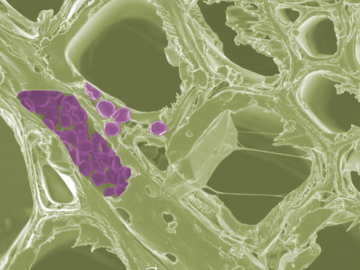

Scientists at the Department of Energy’s Oak Ridge National Laboratory have developed a new method to peer deep into the nanostructure of biomaterials without damaging the sample. This novel technique can confirm structural features in starch, a carbohydrate important in biofuel production.

As the second-leading cause of death in the United States, cancer is a public health crisis that afflicts nearly one in two people during their lifetime.

Peter Wang is focused on robotics and automation at the Department of Energy’s Manufacturing Demonstration Facility at ORNL, working on high-profile projects such as the MedUSA, a large-scale hybrid additive manufacturing machine.

Liam Collins was drawn to study physics to understand “hidden things” and honed his expertise in microscopy so that he could bring them to light.

A select group gathered on the morning of Dec. 20 at the Department of Energy’s Oak Ridge National Laboratory for a symposium in honor of Liane B. Russell, the renowned ORNL mammalian geneticist who died in July.

The type of vehicle that will carry people to the Red Planet is shaping up to be “like a two-story house you’re trying to land on another planet.

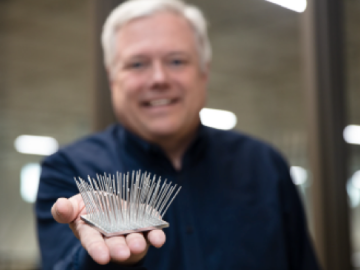

In the shifting landscape of global manufacturing, American ingenuity is once again giving U.S companies an edge with radical productivity improvements as a result of advanced materials and robotic systems developed at the Department of Energy’s Manufacturing Demonstration Facility (MDF) at Oak Ridge National Laboratory.

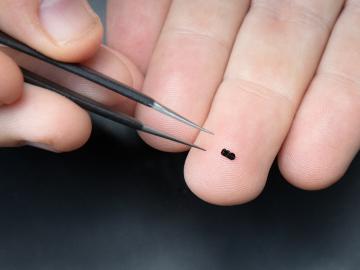

When Scott Smith looks at a machine tool, he thinks not about what the powerful equipment used to shape metal can do – he’s imagining what it could do with the right added parts and strategies. As ORNL’s leader for a newly formed group, Machining and Machine Tool Research, Smith will have the opportunity to do just that.

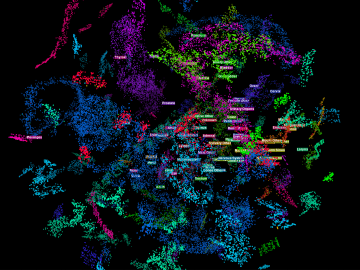

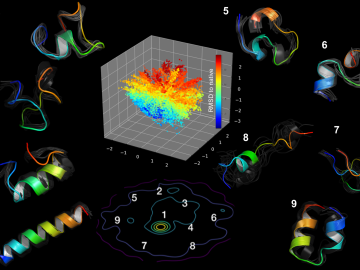

Using artificial neural networks designed to emulate the inner workings of the human brain, deep-learning algorithms deftly peruse and analyze large quantities of data. Applying this technique to science problems can help unearth historically elusive solutions.

Alex Roschli is no stranger to finding himself in unique situations. After all, the early career researcher in ORNL’s Manufacturing Systems Research group bears a last name that only 29 other people share in the United States, and he’s certain he’s the only Roschli (a moniker that hails from Switzerland) with the first name Alex.