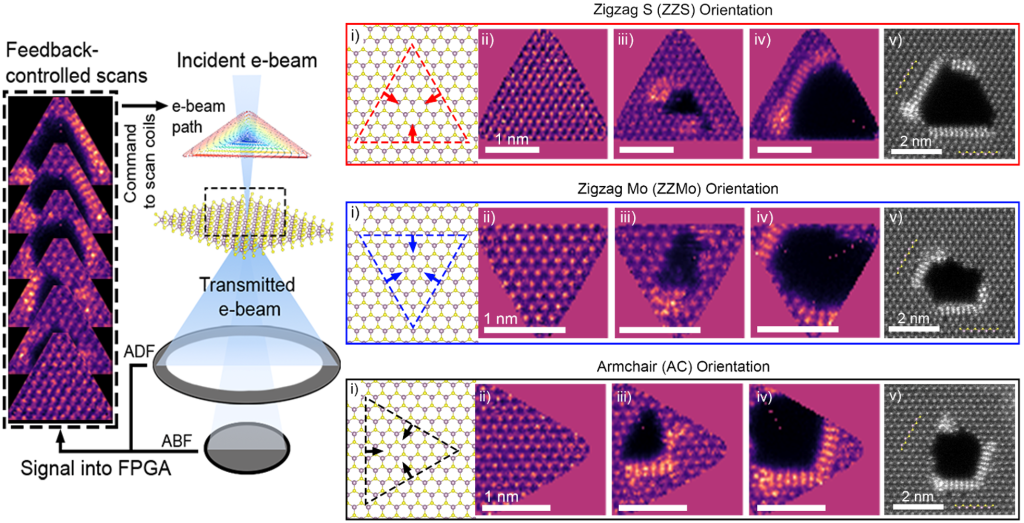

Left: Schematic of automated feedback-controlled workflow allows for controlling scanning beam pathways with simultaneous in situ monitoring during the entire atomic fabrication process. Right: Orientation effects of the triangular shaped scanned drill bit electron beam path show that the zigzag (ZZ) S orientation (top row) produces the most stable triangular nanopore configuration. Triangular milling also demonstrated the formation of MoS-nanowire edges along the ZZS direction, even when aligned along other directions.

Scientific Achievement

Automated feedback-controlled workflow allows for the formation of 1D-2D MoS2 heterostructures via control of the electron beam path shape and alignment along crystallographic directions.

Significance and Impact

Discoveries provide an automated method to induce atomic-scale transformations while opening a pathway towards highly precise atomic-scale engineering of materials.

Research Details

- Preferential S atom knock-out leads to the control of the local chemical potential in MoS2 to fabricate desired 1D-2D edge heterostructures in the STEM.

- Automated beam control through a feedback intensity loop allows for different shaped drill bits, or scan profiles, aligned along crystallographic directions.

- Triangular spiral scans aligned along ZZS direction of MoS2 3-fold symmetry produces stable nanopores with Mo6S6 nanowire edges pathways

M.G. Boebinger, et al., Advanced Materials 35, 2210116 (2023). DOI: 10.1002/adma.202210116

Work was performed at the Center for Nanophase Materials Sciences.